Atomic Urbanism

The following is a short preview of a research project that traces the story of two humble mining towns – the forgotten cradle of the atomic age – in the German-Czech border region of Erzgebirge/Krušnohoří. Through a display of graphic artifacts including maps, drawings, texts, and diagrams, it traces the mining of this inconspicuous metal as a multi-scalar enterprise that entangled and transformed infrastructures, buildings, towns, and whole landscapes on a continental scale. Here, uranium's agency—its radioactivity, its strategic value, its physical properties—is evaluated by examining how it actively shaped buildings, cities, landscapes, behaviours, and biographies once it came into contact with them. From the radioactive dirt under the fingernails and shoes brought into the kitchen, through camp-like city layouts and segregation systems, to territorial transformations of the landscape due to the immense hollowing of the underground—and its dispersal overground.

“First Lightning”

The Soviet Nuclear Warhead Complex

On 29 August 1949, at 7:00 Moscow time (6:00 local time), the first Soviet nuclear warhead RDS-1 was detonated in total secrecy on a desolate expanse of the Kazakhstani desert. At its heart lay a six-kilogramme plutonium core, which was compressed into a metallic orb roughly the size of a fist. Despite its compact design, this piece of inconspicuous metal yielded the explosive power of 22 kilotons of TNT when triggered correctly.

When the countdown ended, the results were extreme and unprecedented. Within a few brief seconds, the detonation released several million degrees Celsius of heat, accompanied by a radioactive shockwave that travelled at the speed of sound. As it advanced, the blast evaporated a series of test structures, military equipment, and aircraft positioned at varying distances from ground zero, destroying them with unseen forces.

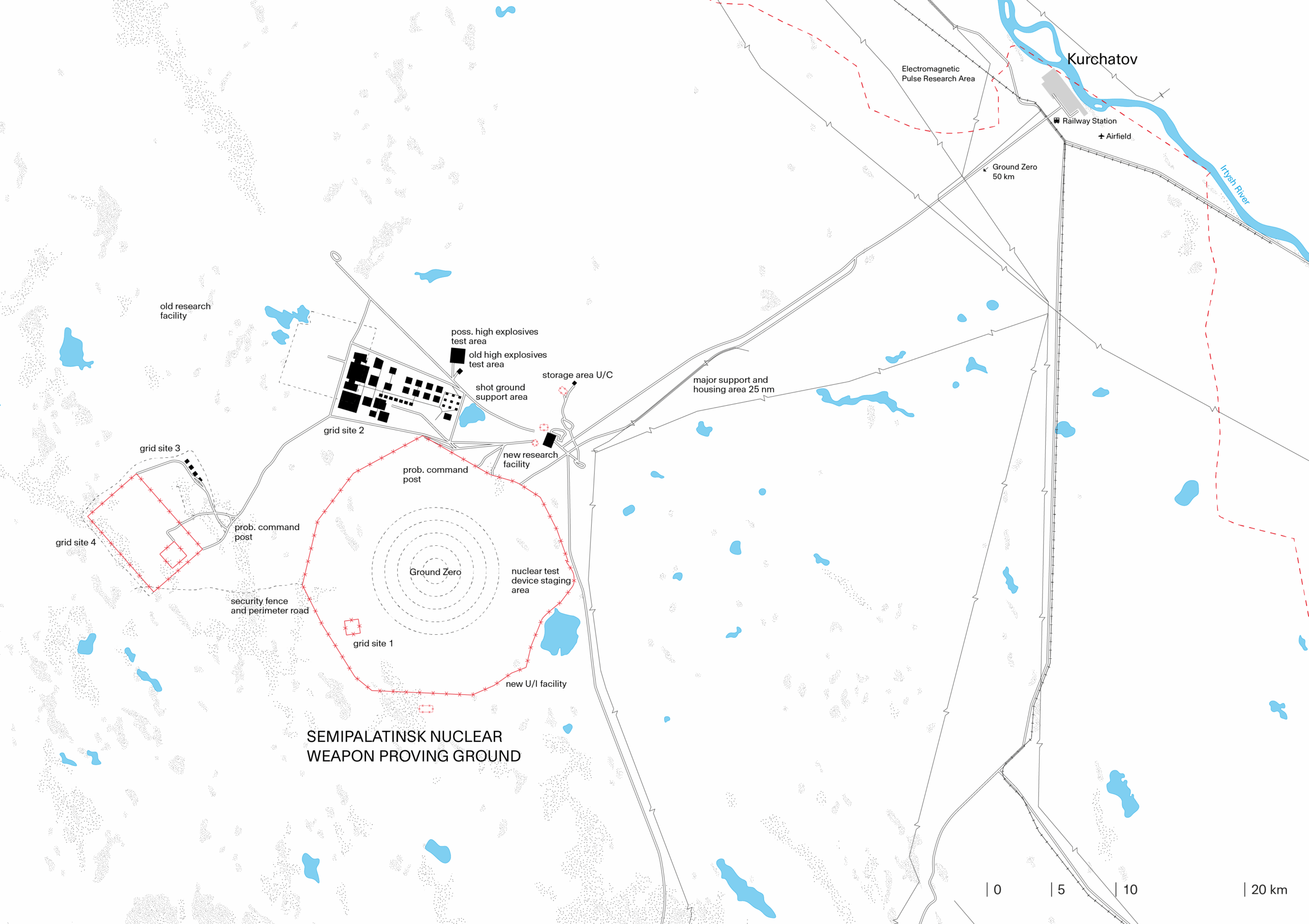

Simultaneously, a black mushroom cloud of radioactive debris, desert dust, and water vapour began to rise. Blown into the troposphere over seven kilometres high, it would spread gamma radiation and large numbers of radioisotopes, including iodine-131, strontium-90, and caesium-137—isotopes that would later become notorious for their devastating biological effects—that were carried on weather currents far beyond the desert plain of Test Site No. 2 (50.43°N 77.83°E), later to become known as Semipalatinsk-21.

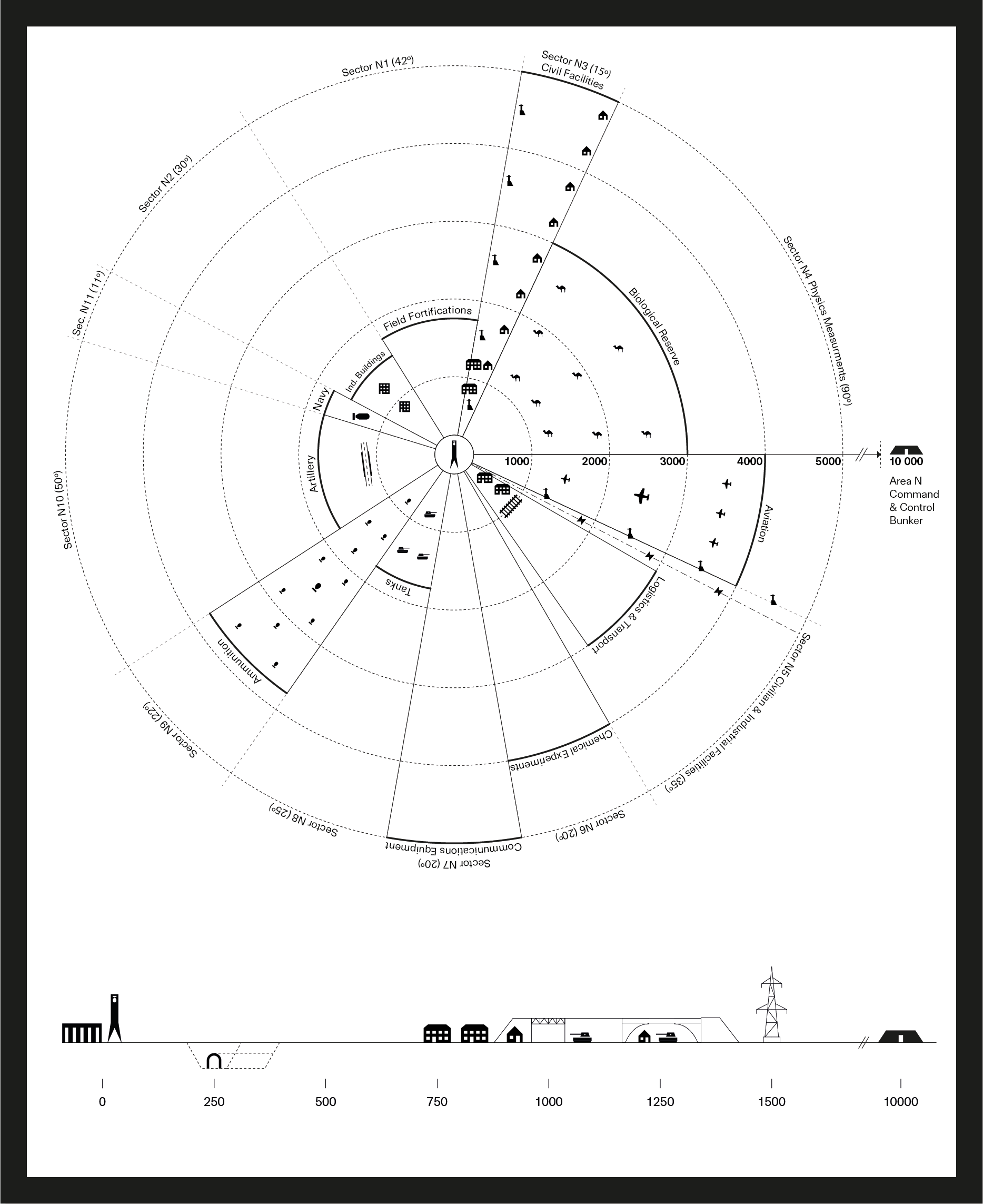

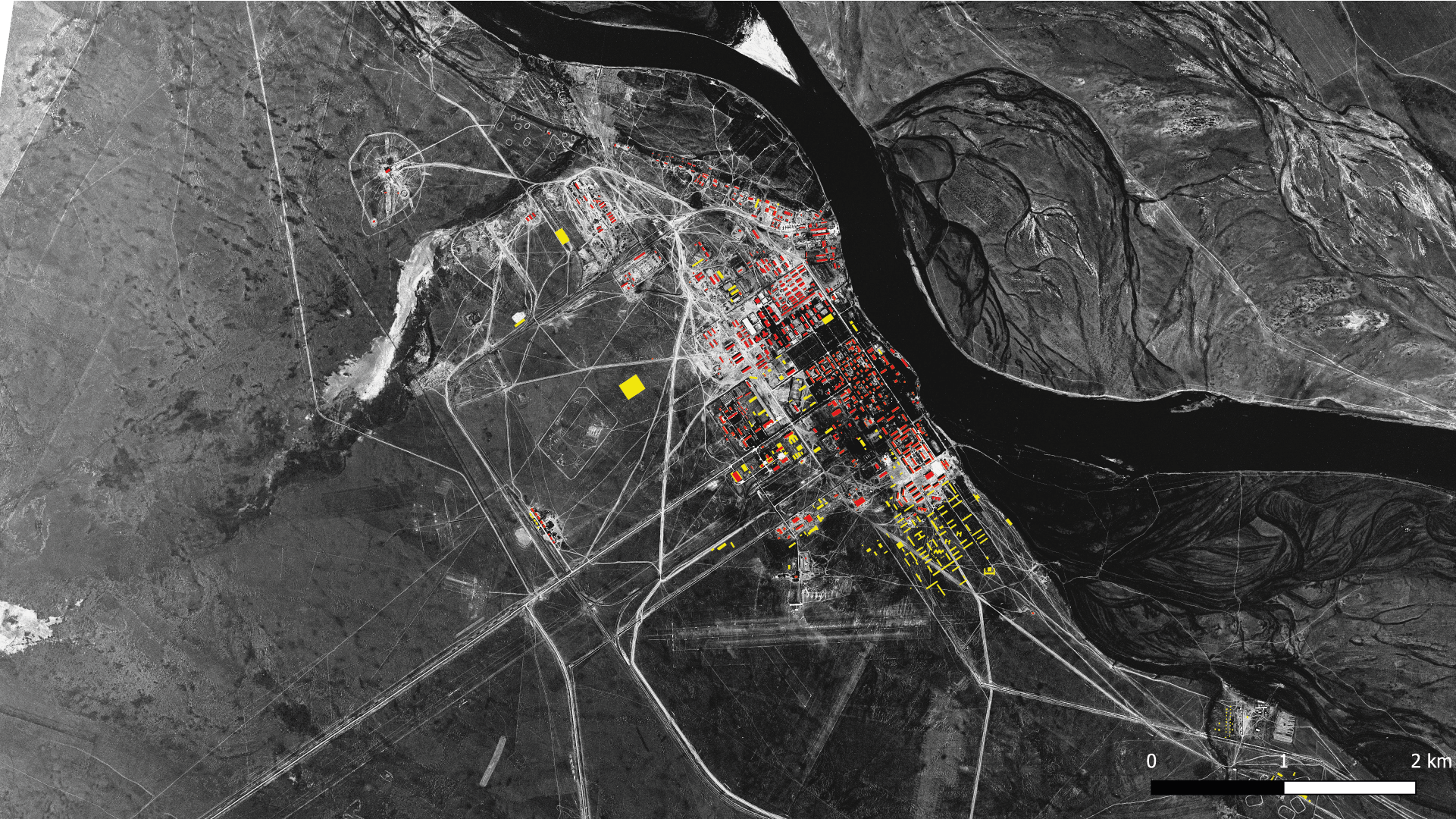

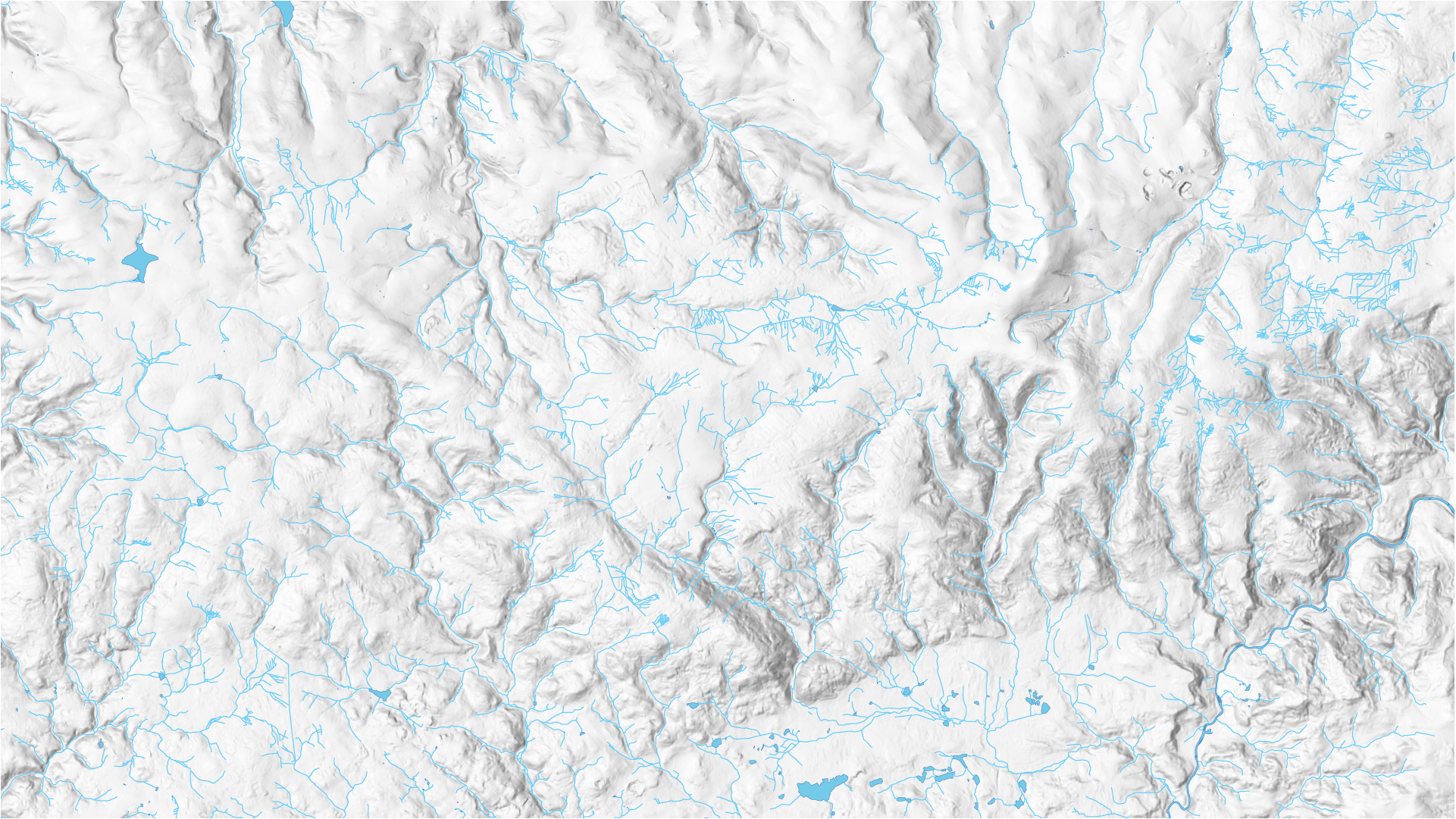

The Semipalatinsk test site encompassed 18,000 km²—nearly the area of Saxony. To service the remote facility, the purpose-built settlement of Semipalatinsk-21 (later Kurchatov) was established on the Irtysh River, approximately 150 kilometres west of the regional trading and garrison city of Semipalatinsk, housing scientists, engineers, and military personnel. The test site's centre, roughly 70 kilometres south of Kurchatov, featured a 30-metre metal tower adjacent to an assembly hall where the RDS-1 device was prepared before being hoisted to the tower's apex. Experimental structures—wooden and brick houses, a simulated metro section, railway with bridge, highway with vehicles, power station, and military equipment—were distributed at calculated distances. Artillery pieces were positioned between 250 and 1,800 metres from ground zero. Two observation posts were established 15 kilometres from the tower: one to the south for military personnel, one to the north for scientists.

Ground-Zero Scheme:

0 m: 30 m high steel tower, carrying the nucler bomb

250 m: metro tunnel dug 15-30 m underground

750 m: two three-story houses

1.000 m: section of railroad complete with metal bridges and two railcars

1.250 m: section of highway with reinforced concrete bridge and automobiles

1.500 m: electric power station with two diesel generators

10.000 m: Area N Command & Control Bunke

At diverse ranges: wide variety of military equipment including tanks, artillery, ships superstructure and aircrafts, one-story houses from wood and bricks, as well as living animals including dogs, swine, rats, mice and two camels.

Kurchatov City

RDS-1

RDS-1 was a pilot project that simultaneously marked an end and a beginning. Its black cloud that hoisted itself up, into the fading dawn of a new age was a brief spectacle, but it represented the collective work of hundreds of thousands of people who had been driven at innumerable cost and pain to forge a delicate balance of power.

RDS-1 literally broke ground for something the emerging U.S. American rival had not deemed possible for many years to come. Manhattan Project designs had been transported through spy networks from the camps of Los Alamos to Russia, where German and Soviet scientists worked on the science and technology that would allow to produce their carbon copies. Meanwhile a clandestine group of functionaries and generals commanded hundreds of thousands of forced labourers and Soviet soldiers to establish the foundations of the Soviet nuclear industry throughout the immense continental landmass of Eurasia. Operating at an unprecedented scale in a war-devastated country, this early connection of a handful of highly classified and secretive sites formed the prototypical infrastructure that would be refined and expanded to sustain the USSR's atomic shield.

RDS-1 was a proof of concept. In its wake, the crash programme that had amalgamated laboratories, machines, factory compounds, industrial infrastructures, natural resources, vast workforces, and entire landscapes needed to expand rapidly to deliver nuclear parity with the already accelerating production of the United States. In the following decades Semipalatinsk-21 would become the setting for nearly 500 nuclear weapons tests. Between 1949 and 1990, the Soviet Union conducted a total of 715 tests with 969 individual devices—211 atmospheric tests and 496 underground tests. When the site was finally shut down in 1991, the USSR possessed roughly 35,000 strategic warheads, a startlingly high number given that they had already begun disassembling their nuclear stockpile after it peaked in the mid-1980s. Their production capacity for warhead manufacturing and refurbishment each year remains unclear, but official reports and estimates vary between 2,000 and 7,000 pieces per annum. Underlying all of this were colossal quantities of uranium.

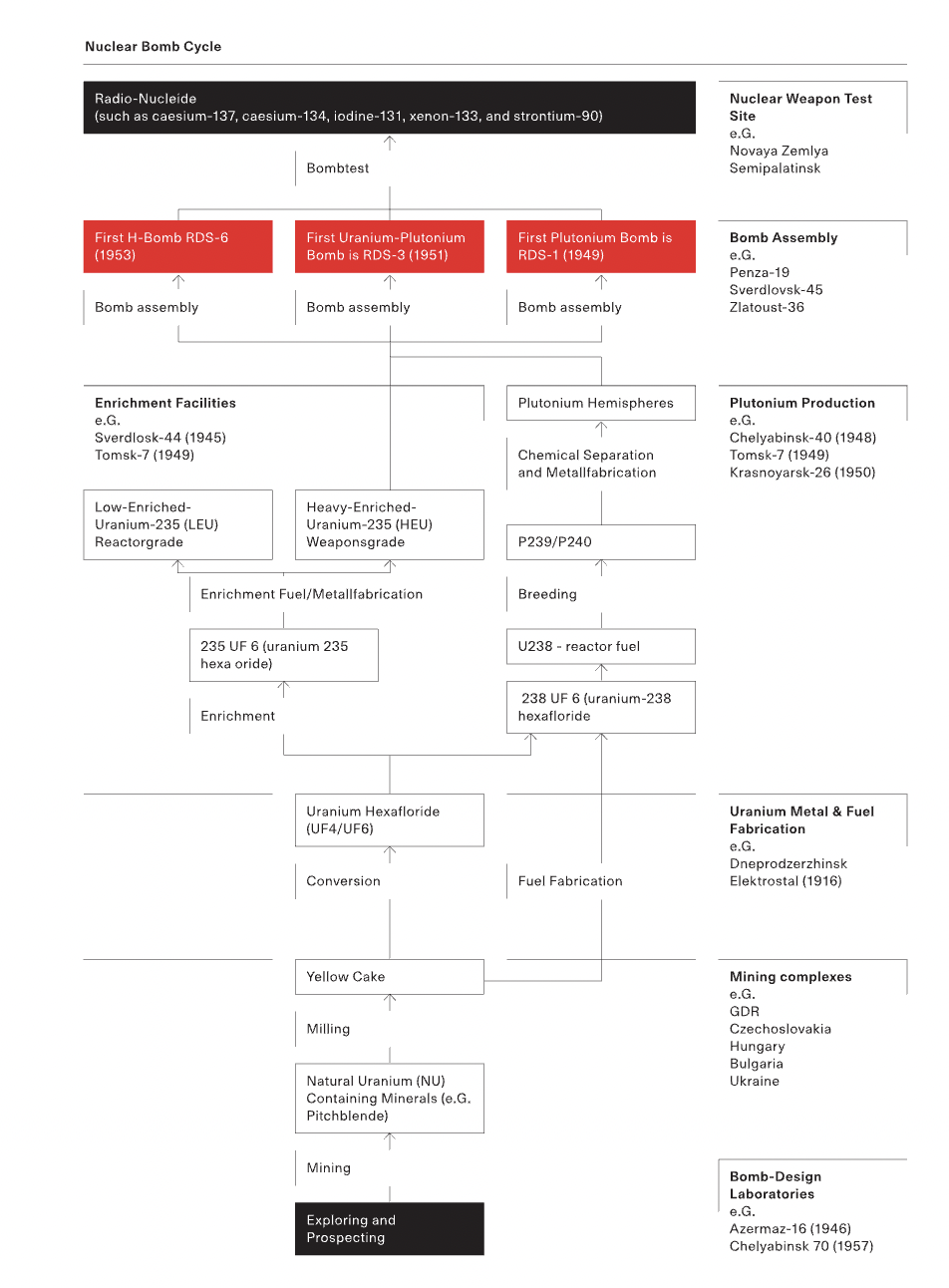

The initial wave of Soviet nuclear facilities emerged in the second half of the 1940s, exclusively invested in developing a functional bomb prototype by reproducing the U.S. design as rapidly as possible. This initial infrastructure comprised three main laboratories and three major production sites, tasked with supporting the armament industry. Deemed too sensitive to emerge amongst the urban centers of European Russia, they were strategically distributed across the peripheral industrial belt of the Ural Mountains and Siberia. The fledgling supply chain that produced RDS-1 followed a pattern of nuclear weapons materials production copied by the United States: construction of natural-uranium-fueled, graphite-moderated thermal reactors for plutonium production, supported by a metallurgical plant, a weapons laboratory and the eventual testing ground.

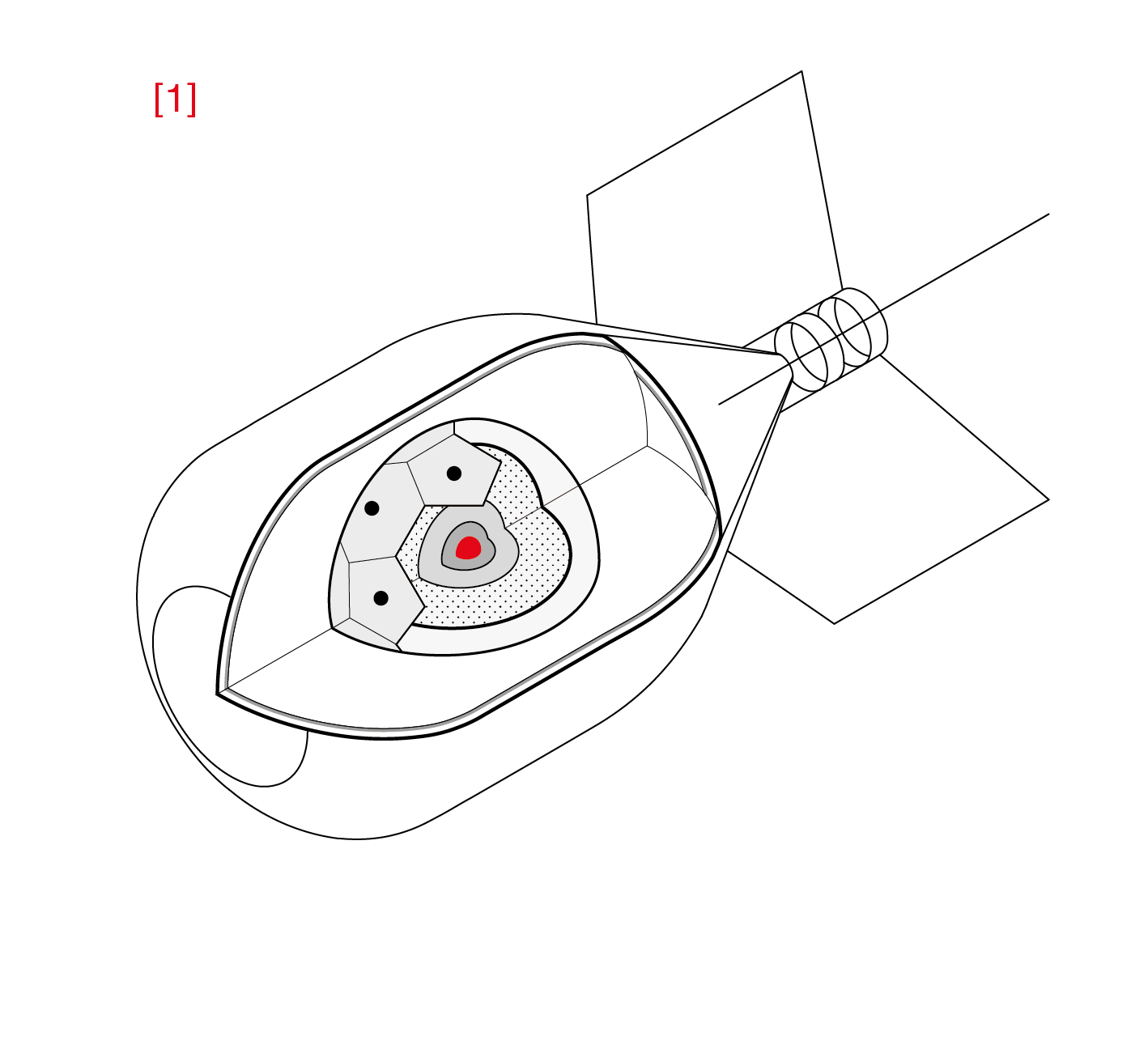

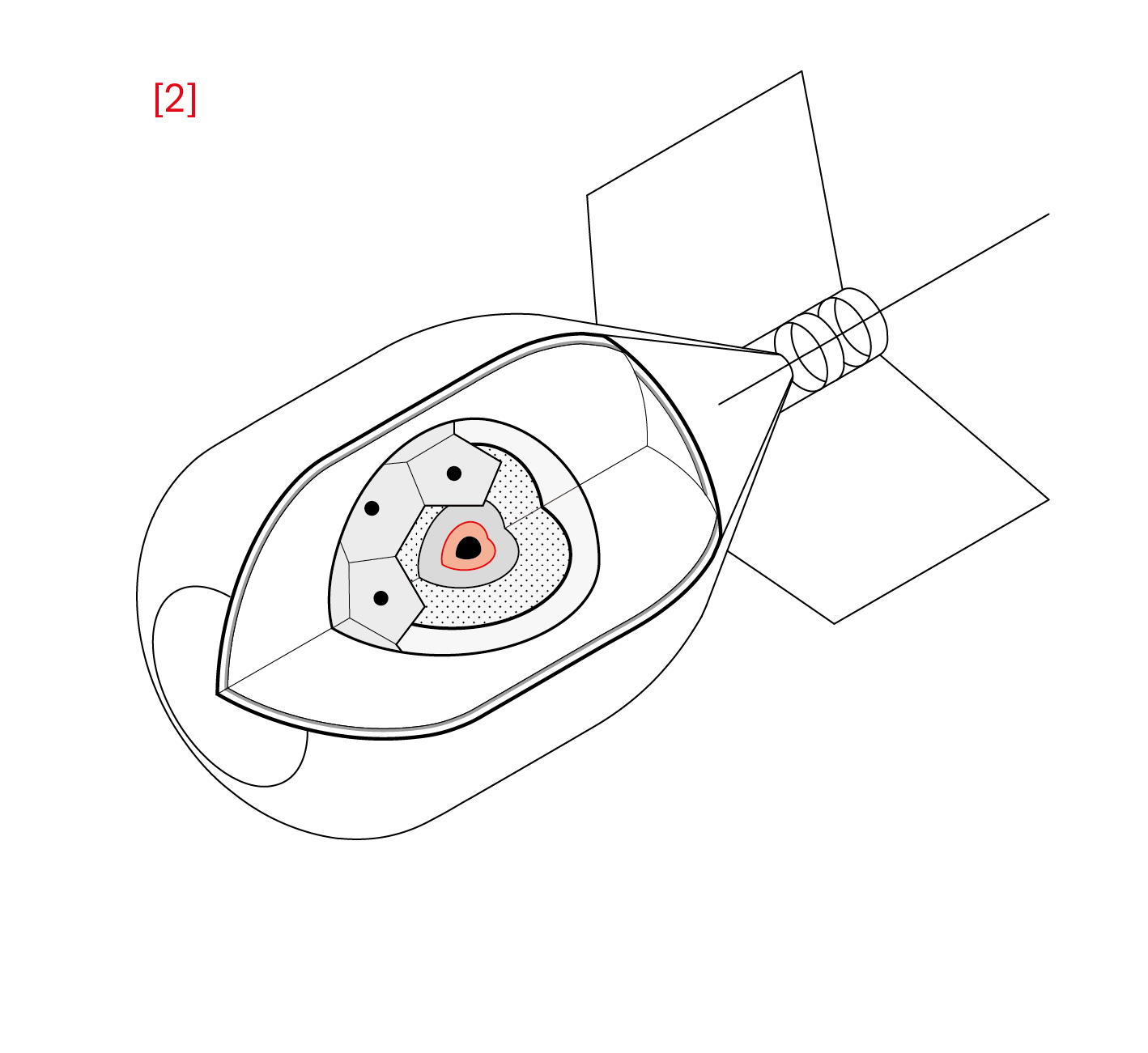

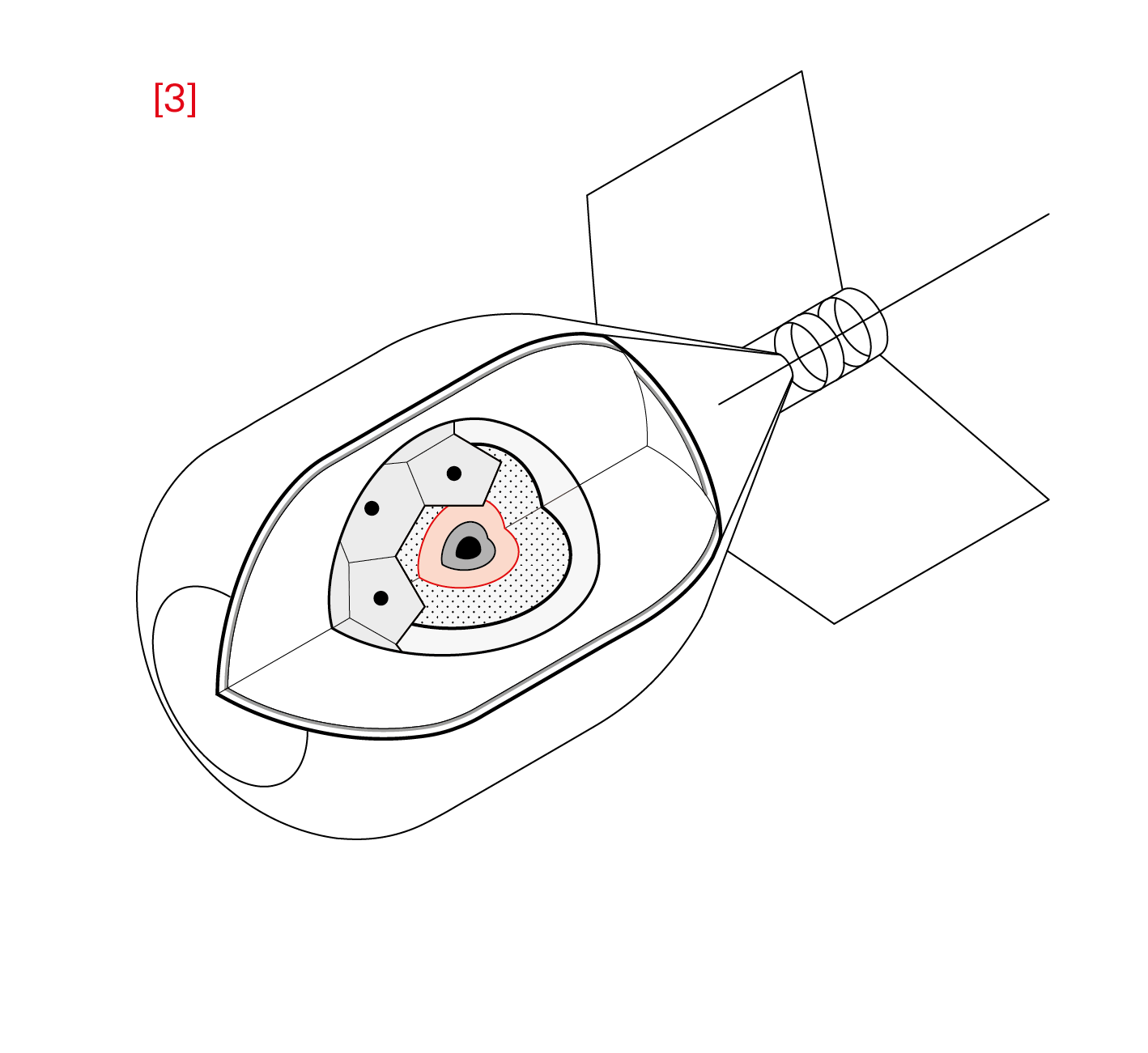

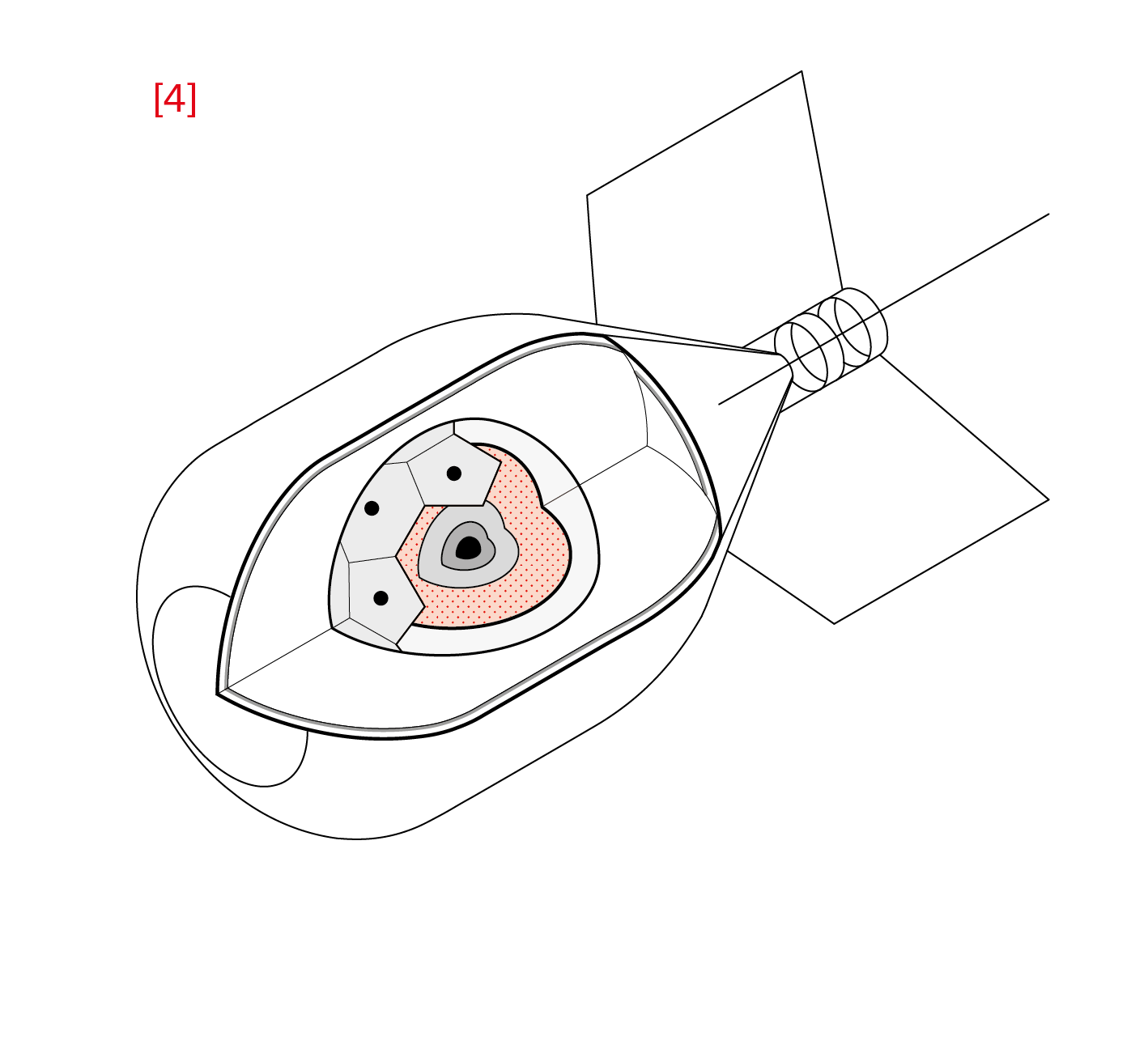

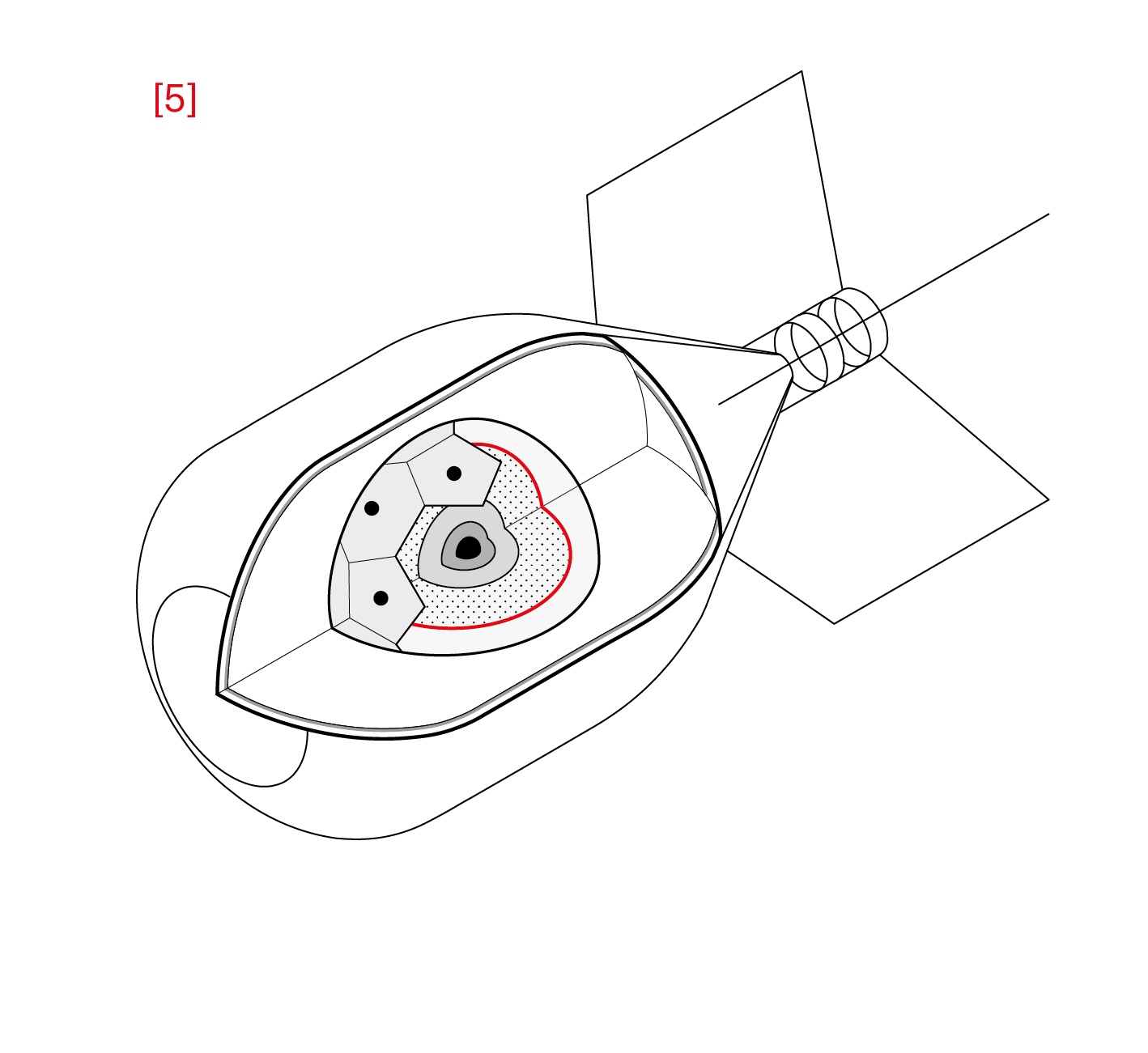

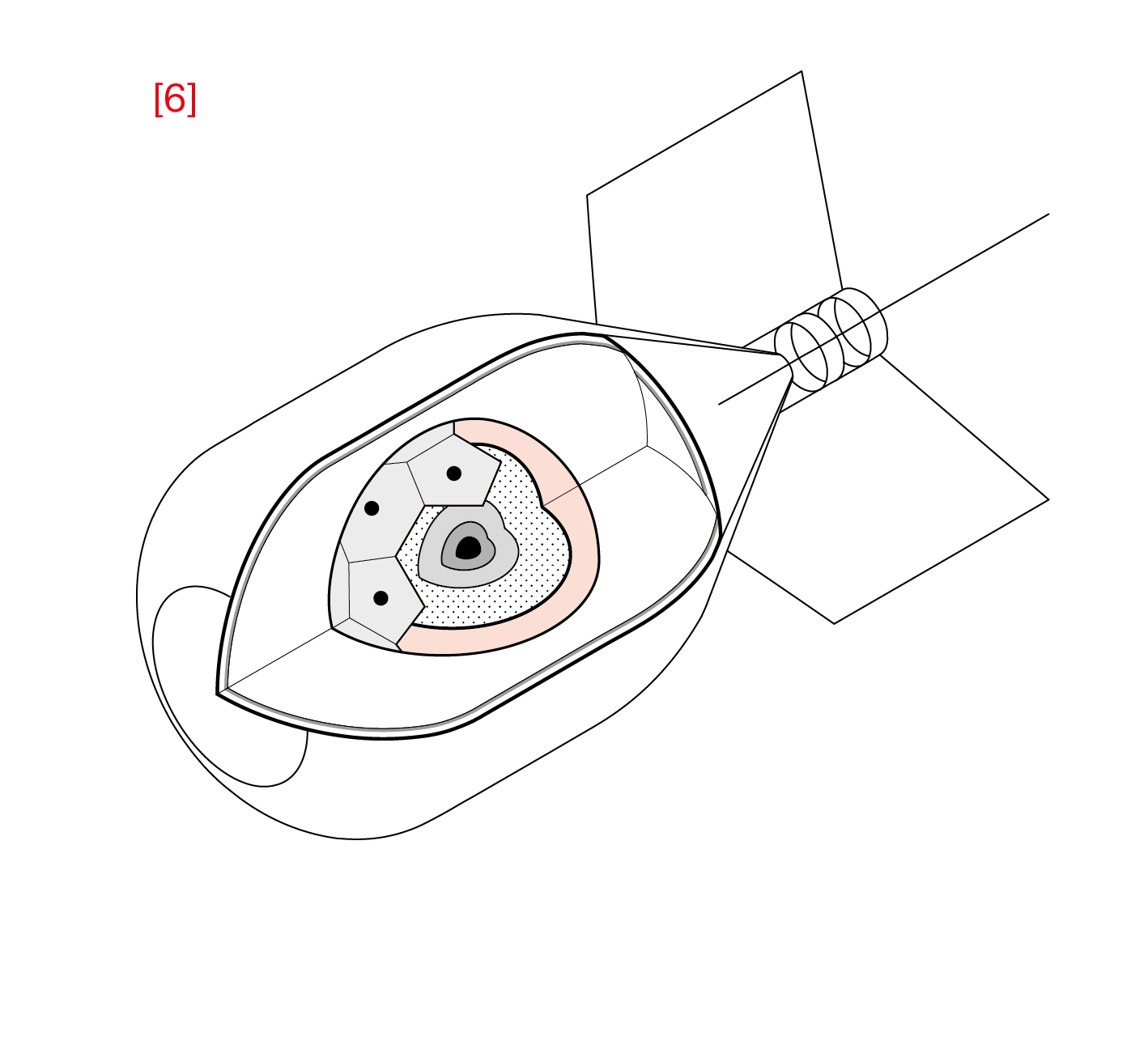

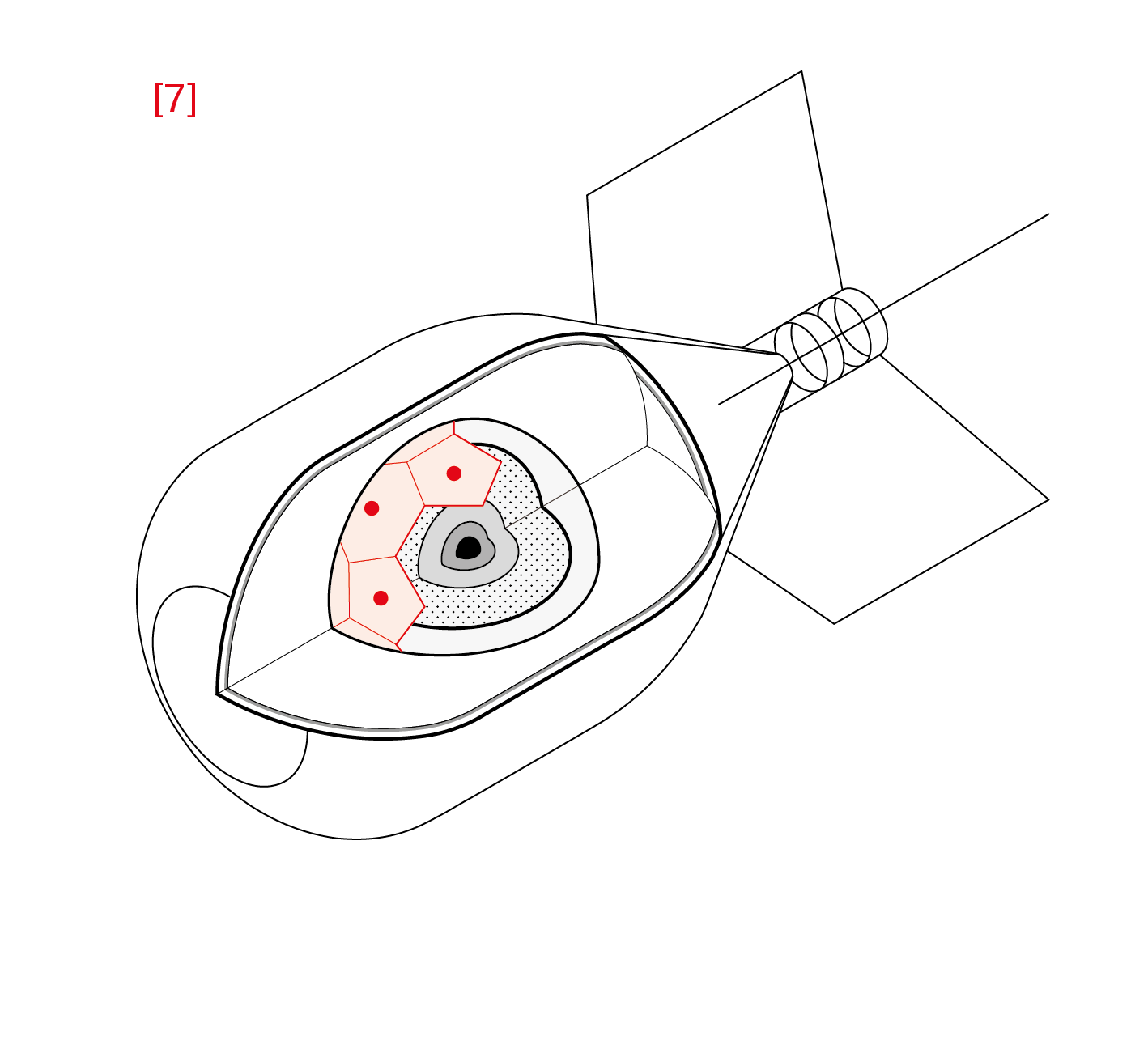

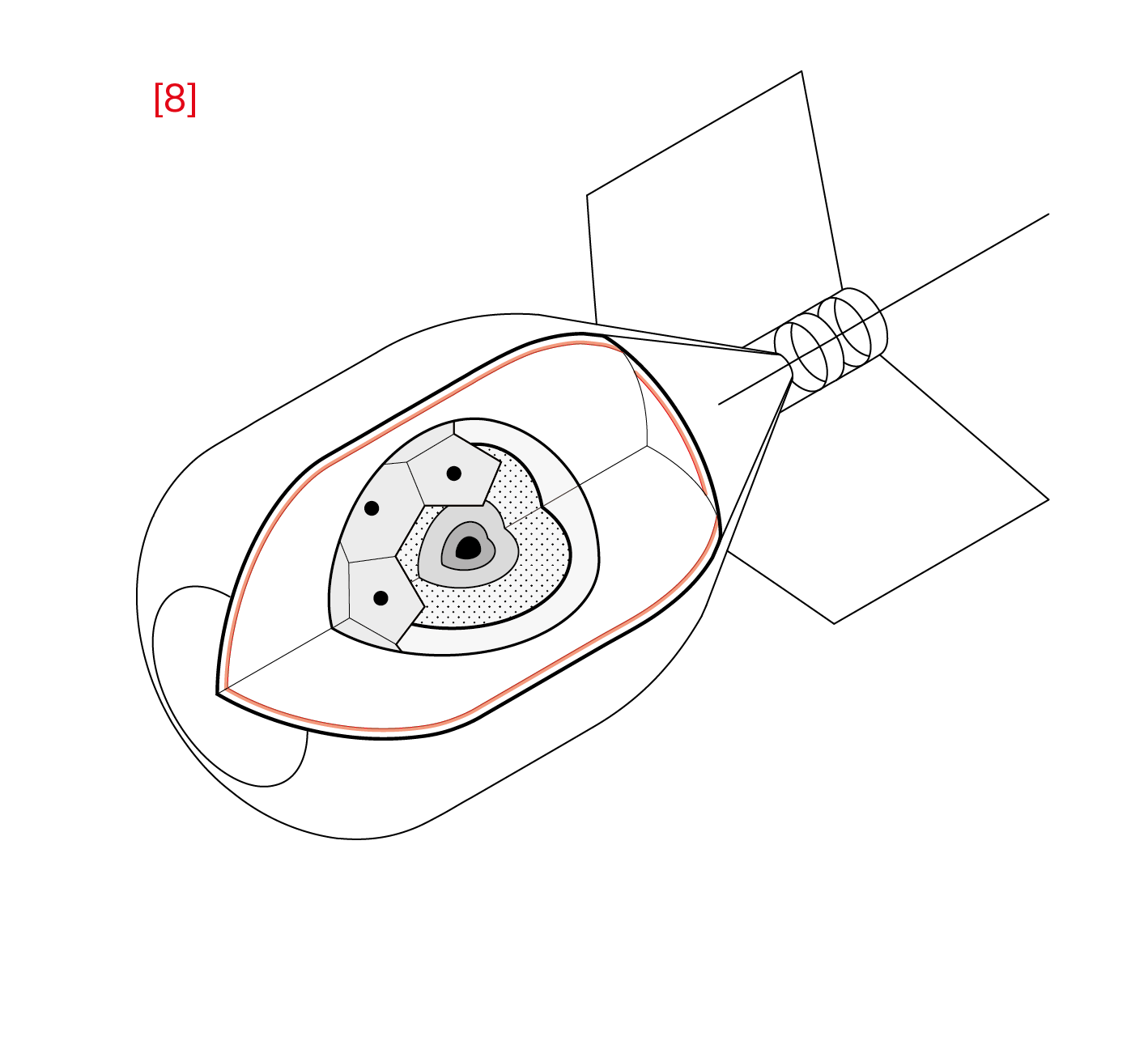

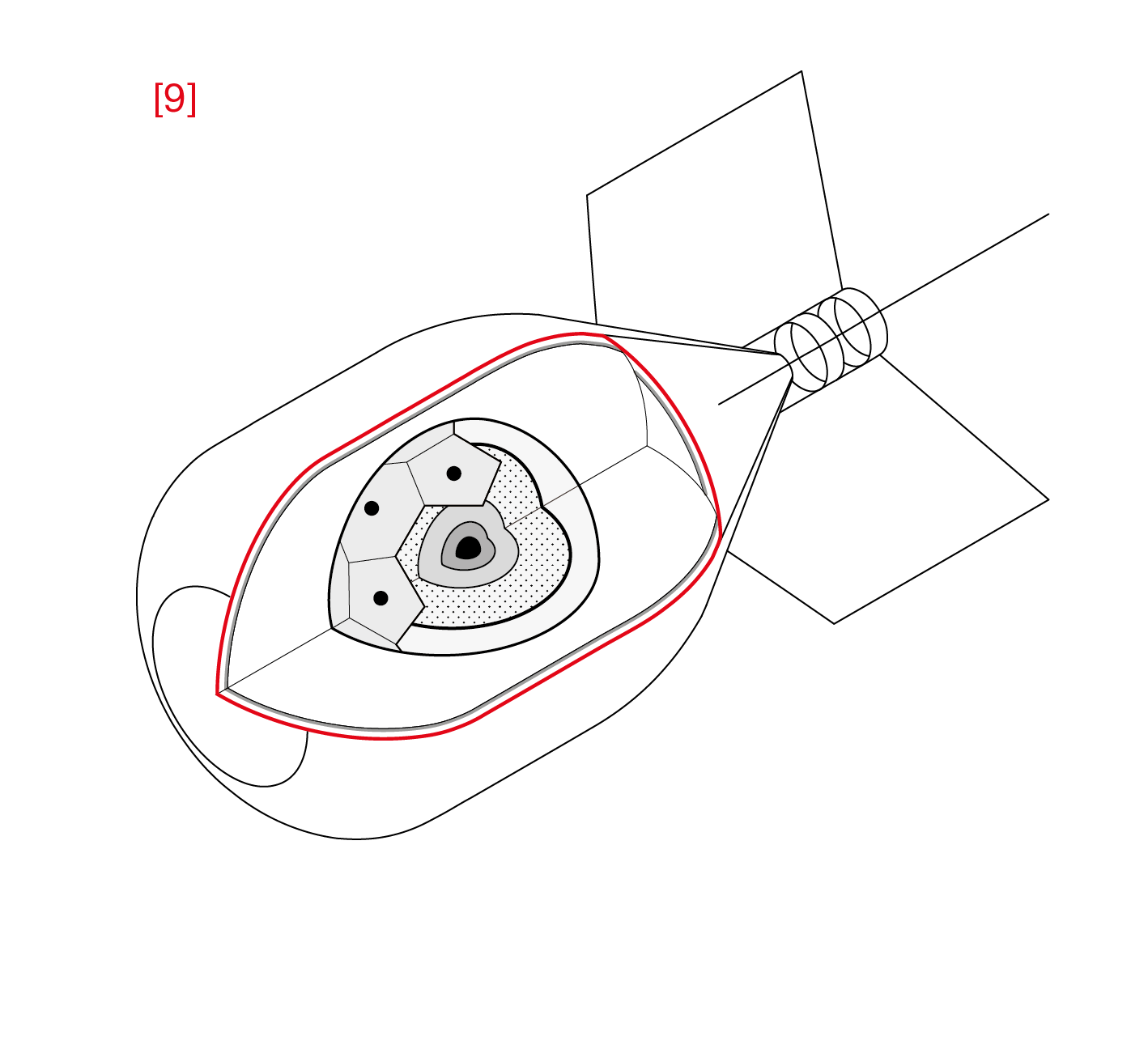

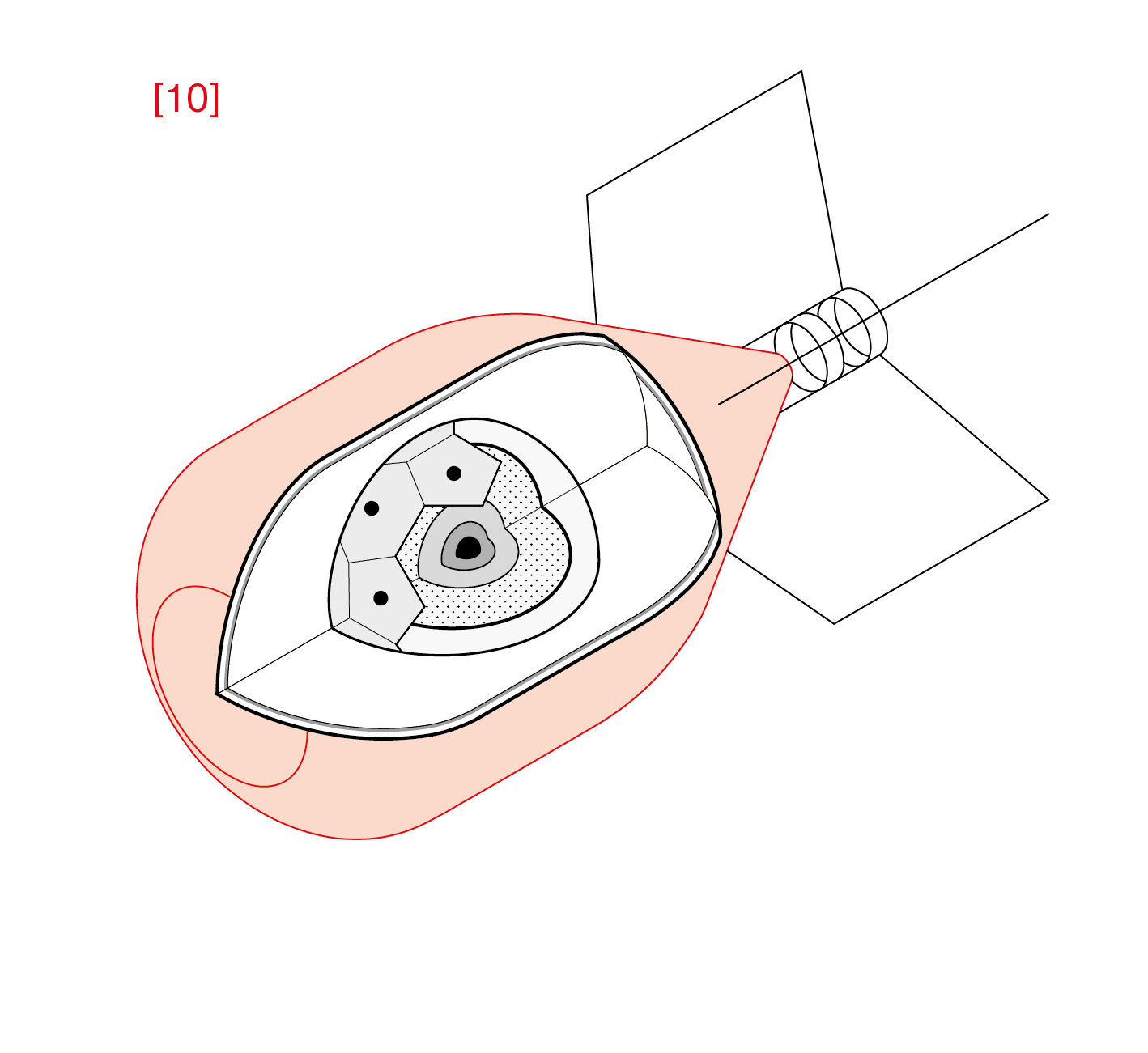

[01] Neutron initiator within a plutonium core

[02] Uranium tamper

[03] Aluminium pusher

[04] (Comp B) Explosive booster back

[05] Slow explosive lens element

[06] (Comp B) Fast explosive lens element

[07] Detonator

[08] Dural shell with a cork liner

[09] Air space

[10] Steel ballistic case

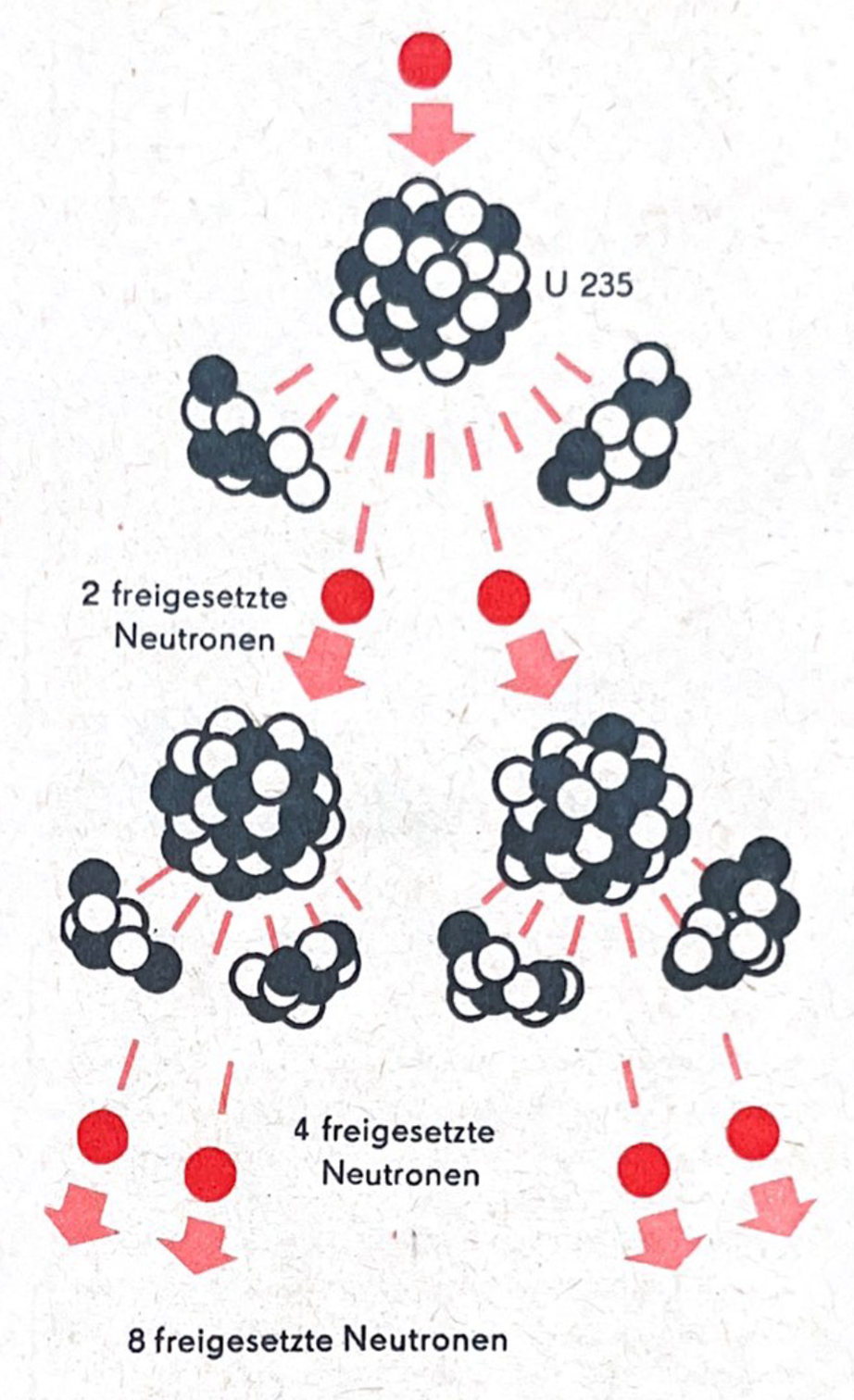

Central to the architecture of a nuclear bomb is the precise assembly of fissionable material into a critical mass. The goal of any nuclear weapon is to enable a chain reaction of increasing velocity that releases maximum energy in fractions of a second. RDS-1 employed an implosion-type assembly, achieving supercriticality through the rapid compression of a subcritical plutonium core. Upon detonation, conventional explosives surrounding the core reduced its size, which in turn massively increased its density, resulting in an explosive chain reaction. This mechanism relied on the unification of two subcritical pieces of highly enriched material colliding with sufficient velocity to create a single supercritical mass.

Transferring pilot experiments from the laboratory to industrial scale and mass production was no small feat and often included the invention of entirely new streams of large technical systems and fuel cycle technologies that were far from the lab-desk-designs. Whether the aim was the production of fuel or weapons, the science needed to be readapted for the factory. However, scaling up presented new complications. Two initial tasks had to be mastered at the same time. The first one obviously involved the invention of a functional nuclear explosive that would trigger an exponential chain reaction; the second, no less crucial, had to solve the production of stable radioactive fuel from uranium-bearing minerals at a constant level.

As uranium proceeds through the various steps in its processing - accumulation, purification, enrichment, transmutation - it becomes more delicate and more hazardous. Accommodating this volatility while transporting and preparing the material on such a massive scale required countless spontaneous innovations. The head scientists in charge of the research and development programs had the delicate task of communicating their often-mind-blowing results in a practical way to engineers, plant managers, planners and political leaders. They, in turn, had to organize industrial production lines and the new atomic infrastructure, based on largely invisible phenomena, with potentially cataclysmic consequences when scaled up wrong. In parallel, a highly specialized new workforce of technicians, lab scientists and laborers responsible for operating the new machines and production cycles had to be educated and attracted quickly.

.

URANIUM Atomic

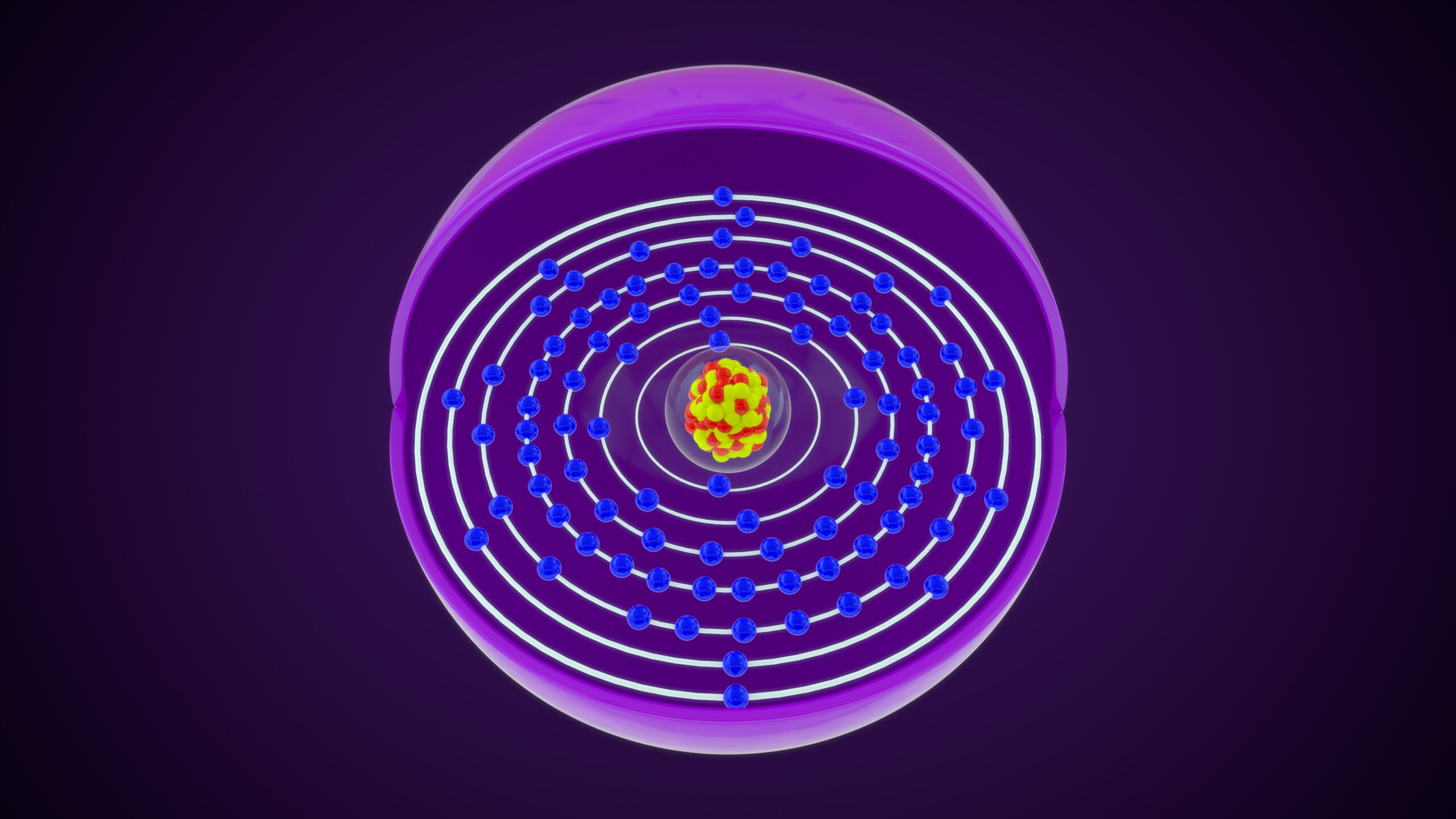

Uranium is a heavy metal and the heaviest naturally occurring element, with the atomic number 92. Uranium marks the unequivocal border in the periodic table of elements: whereas it along with the preceding 91 elements are all naturally occurring, from neptunium (93) onwards, each one is engineered by man. The uranium we find on earth today is a direct result of stellar processes from a time beyond our planet’s when mythic amounts of energy were free at play. As this occurred before the earth was formed, every piece of it we find today is over 4.5 billion years old, what is known as a primordial nuclide. Even with all of mankind’s ingenuity, we cannot create it anew. We must seek it out, dig for it, and carve it from earth’’s crust wherever we are (un)fortunate enough to find it.

The elements following uranium on the periodic table are known as transuranic elements, a classification derived from their engineered evolution. These were developed, by bombarding the atomic cores of certain very heavy natural elements (such as uranium or thorium) with subatomic particles, in a process called transmutation that describes the conversion of chemical forms from one state to another. Although this required the conception and development of laboratories, technical installations and city-sized machines that would use and produce amounts of energy unseen before the 20th century, these efforts blush in the face of the supernova required to form uranium itself. The reason for uranium's divisive place in the periodic table lies in its innate atomic qualities: it has a very large, but highly unstable core. It is constantly at the verge of bursting; it seems to exist at the limits of an unnatural decadence scarcely tolerated by our natural laws.

Fundamentally, all atoms consist of an outer shell of negatively charged electrons that gravitate around a nucleus or core made of positively charged protons and uncharged neutrons. In a tantalizing feat of physics, the total mass of the core is always less than the combined single masses of the protons and neutrons that make it up. This difference is accounted for by a measure of something called nuclear binding energy. Simply speaking, this is the force that holds a nucleus together. Larger cores tend to have less binding energy, meaning that these binding forces are unbalanced in relation to the forces that pull them apart. In order to stabilize themselves, they are continually slimming down, constantly releasing subatomic-particles in a natural process of decay. Quite an exhaustive condition. We commonly call this automatic, inherent decay of unstable atoms radioactivity, or radioactive decay.

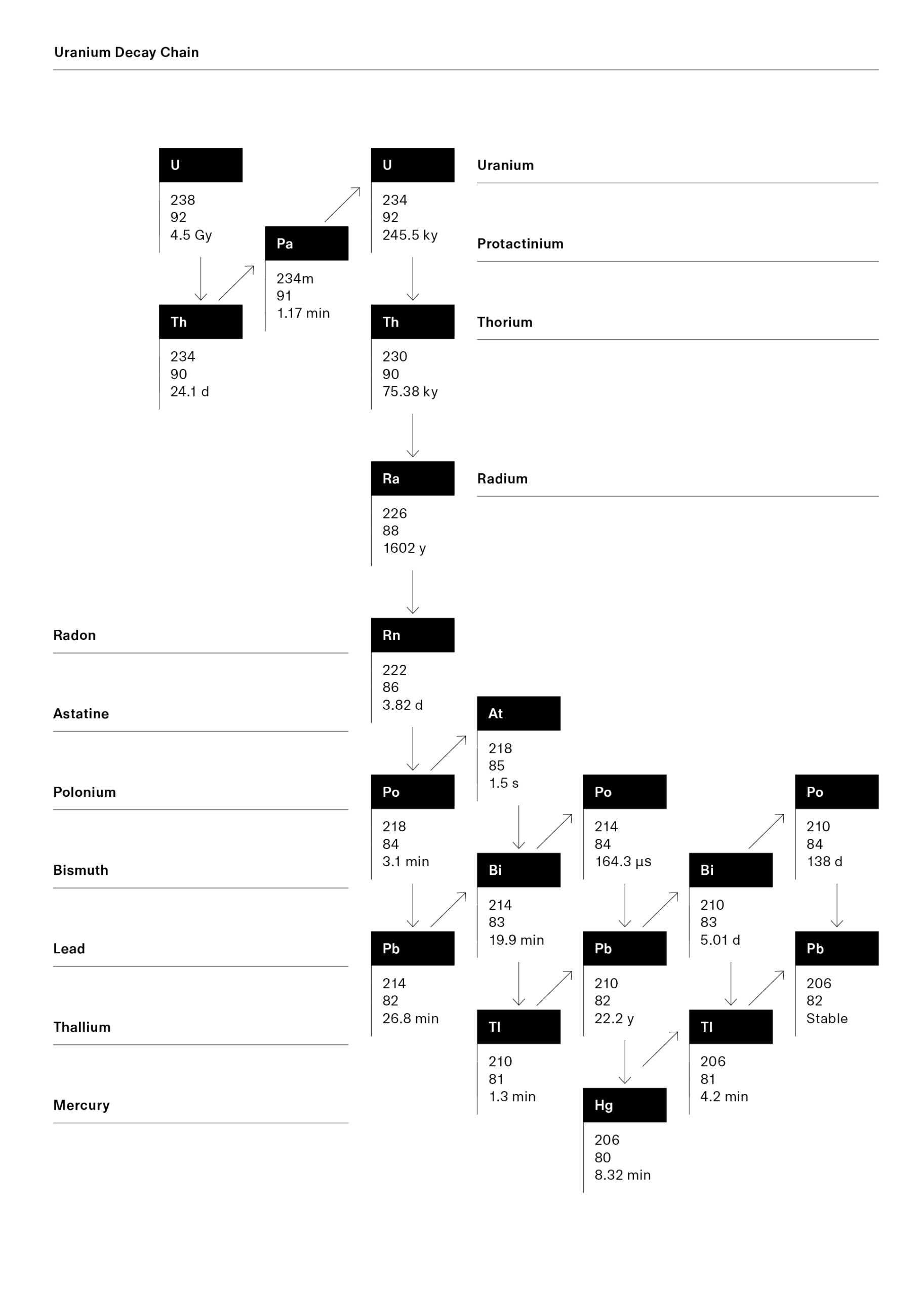

Despite its wobbly core, natural uranium (NU), that is uranium found in nature, is only mildly radioactive. Its radioactive decay is incredibly slow, and as it gradually, continuously loses particles and atomic mass, it transmutes through other unstable elements, such as thorium (90Th), radium (88Ra), radon (86Rn) and polonium, until it becomes lead (82Pb). Lead is the last stable element in the periodic table, and given enough time, every unstable element will become ‘leaden.’ The length of such decay is the element’s half-life, the time it takes for half the amount of unstable nuclei in a given element to decay. Depending on its isotopes, its chemical variations, this time ranges with uranium from a few hundred centuries up to four and a half billion years. Deep time. Mythic time.

.

URANIUM Mineral

Although natural uranium can be found in a wide variety of geological environments and is now considered rather abundant, this has not always been the case. Predictions for uranium resources worldwide were particularly grim in the early years of the Nuclear Age, triggering a global rush for extraction. This extended post-war colonial exploitation into regions such as the Belgian Congo and southern Africa, whilst simultaneously spurring massive prospecting campaigns across the United States, Canada, Australia, Eastern Europe, and Soviet Central Asia.

The concentration of natural uranium varies significantly depending on geological setting, but averages approximately 2.8 parts per million (ppm) within the Earth's crust. One of the most significant minerals in which uranium is found is uraninite, a compound mineral that largely consists of uranium dioxide (UO₂) along with other byproducts of its radioactive decay, such as actinium, polonium, radium, and lead. It varies in shape and form from crystalline geometry to vesicular, amorphous masses. Although commonly dark in colour with an almost greasy lustre, it often ranges from velvet-black to pale green, and can exhibit even brighter hues.

Formerly known as "Pitchblende" or "Pechblende," uraninite was initially unearthed in traditional silver mining operations in the mountainous border region of Erzgebirge/Krušnohoří more than four hundred years ago—making this region the cradle of uranium's discovery. When first found, the ore had no value for metallurgy and was often disposed of in heaps outside the mines. With time and exposure to the elements, uraninite oxidises and gains remarkable yellow hues known as gummite, a trait that would eventually attract the attention of Europe's scientific community. Samples of this curious black rock found their way into private collections of naturalists and chemists throughout the continent.

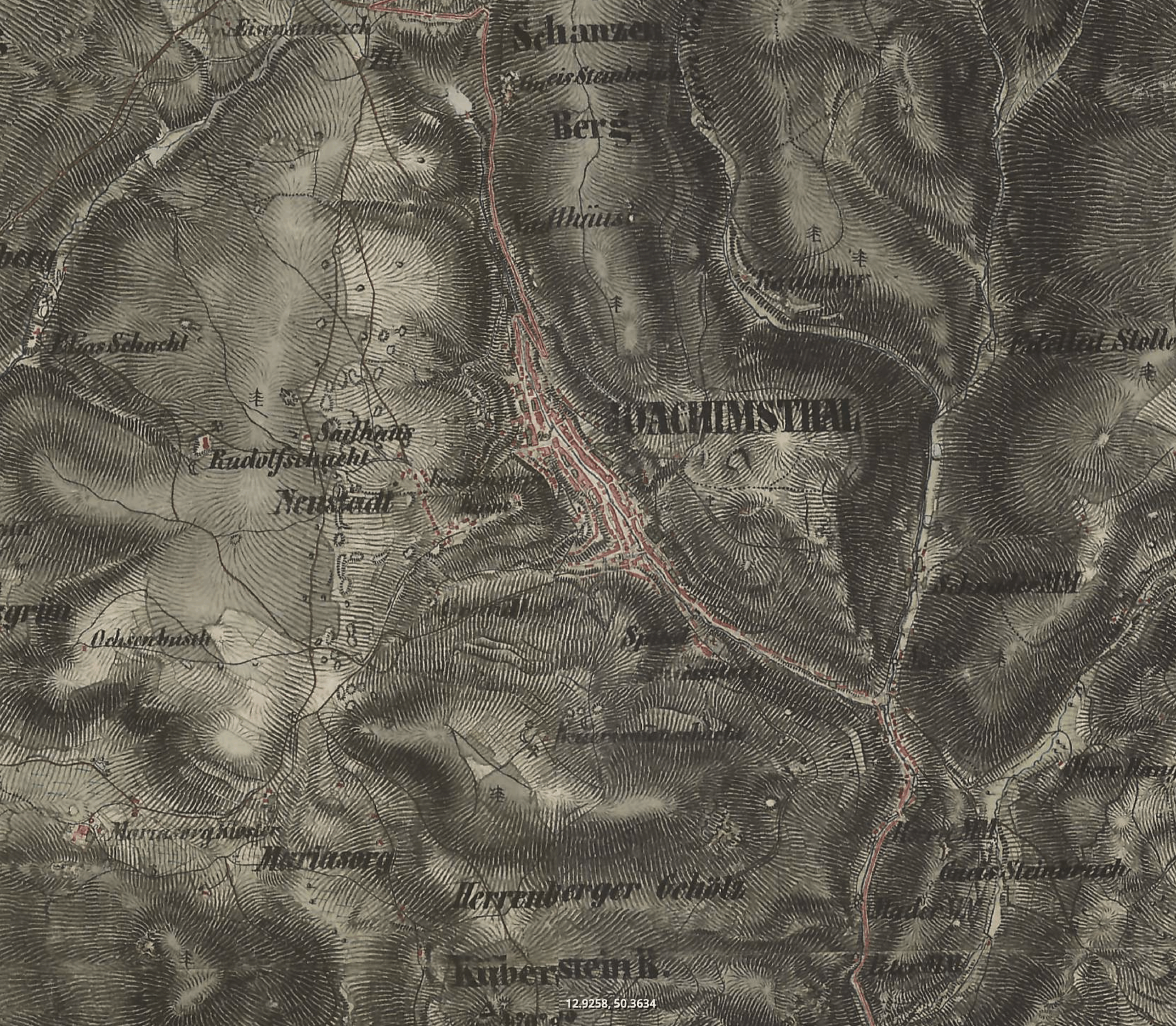

In 1789, the German apothecary Martin Heinrich Klaproth, working in his laboratory in Berlin, received a sample of black rock—Pechblende—extracted from a small mineshaft known as the Georg Wagsford Shaft in Johanngeorgenstadt. Although commonly disregarded by miners and discarded as waste, the substance had already been described more than half a century earlier. Klaproth's investigations would prove far more influential than could be understood at the time. When he diluted the Pitchblende in heated nitric acid, he succeeded in isolating a black powder containing a previously unknown chemical element. He named this new element "uranium," in honour of the planet Uranus, which had been discovered some years earlier by the German-British astronomer Sir Friedrich Wilhelm Herschel.

Johanngeorgenstadt und Jáchymov -

The Forgotten Cradle of the Atomic Age

For decades, uranium remained a laboratory curiosity whilst pitchblende continued to accumulate in waste heaps across the Erzgebirge/Krušnohoří. Yet samples of this despised mineral would prove to be one of the most consequential substances of the modern era. Two mining towns in this border region became the forgotten cradle of the atomic age: Johanngeorgenstadt on the Saxon side and Jáchymov in Bohemia, separated by just 40 kilometres of mountain terrain.

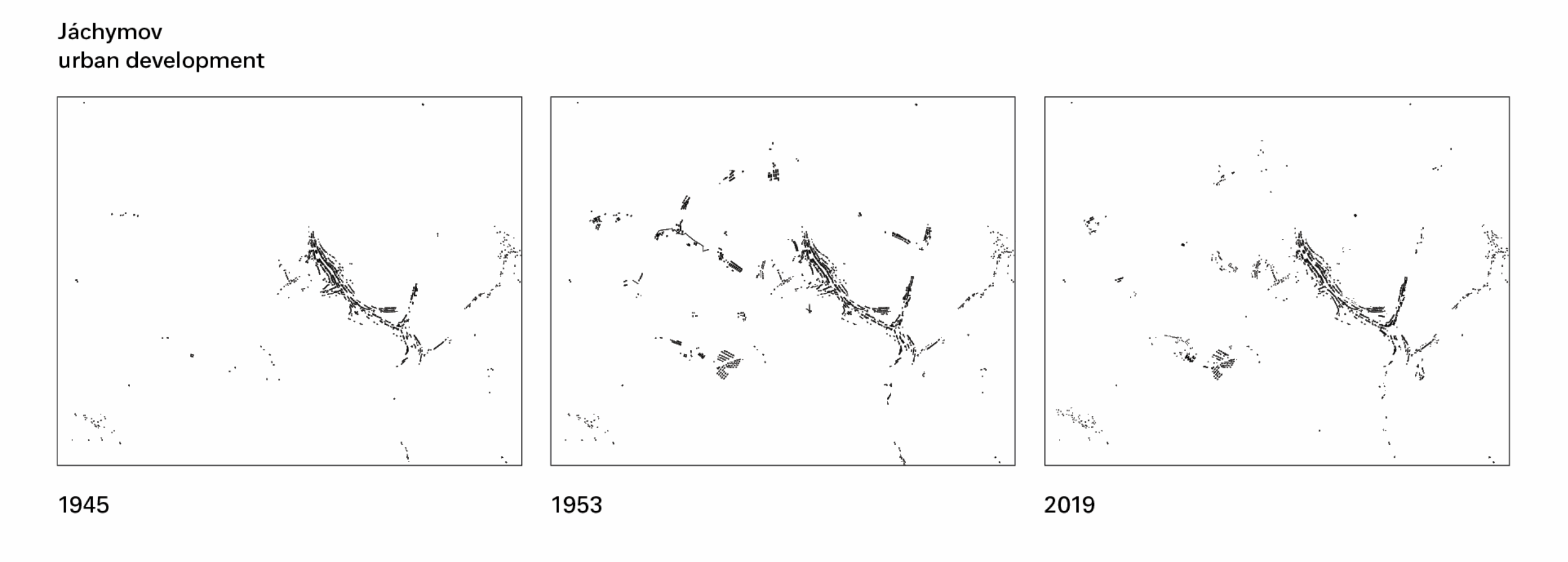

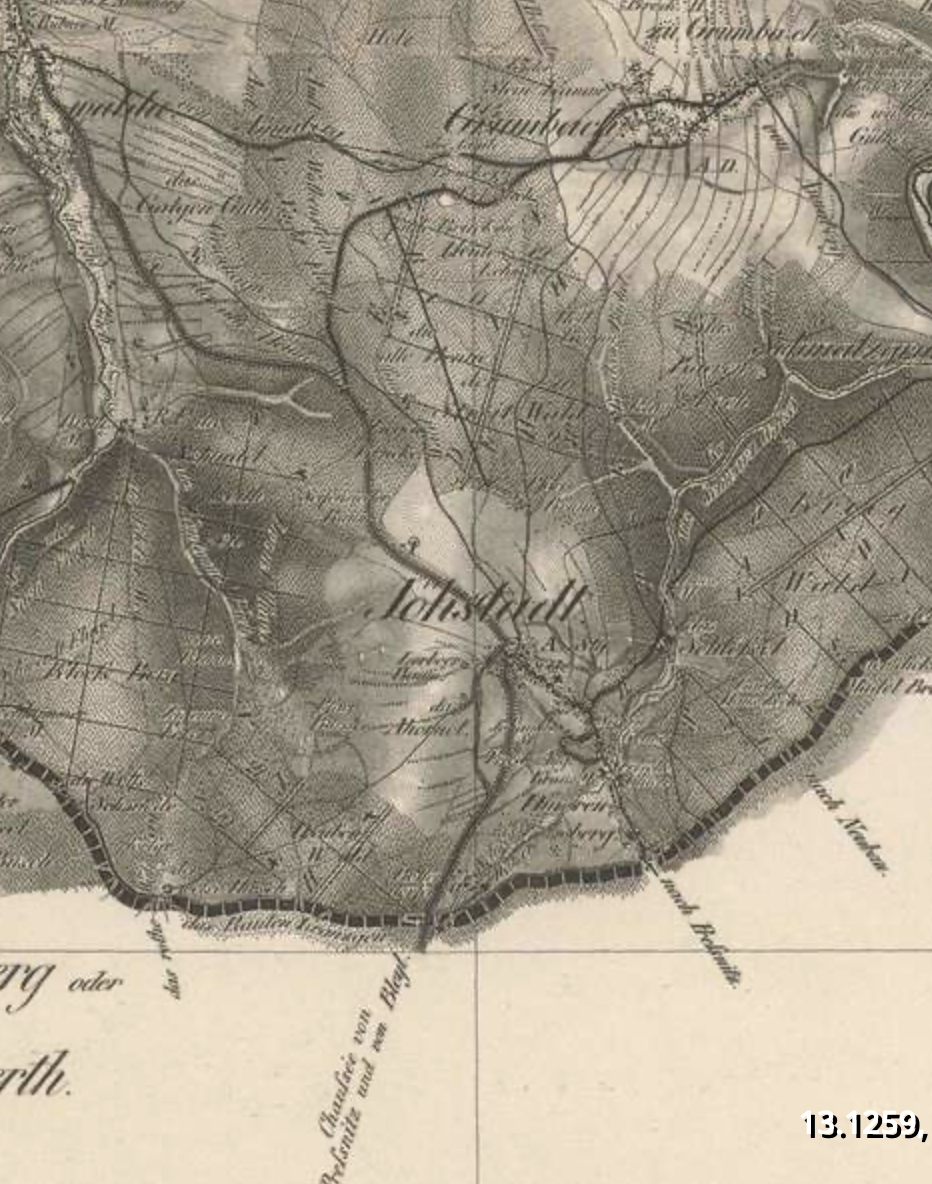

Though both towns shared a mining heritage stretching back centuries, their trajectories had diverged considerably by the early twentieth century. Jáchymov, with its medieval origins and silver-mining prosperity, had evolved into a modest spa town of around 6,500 inhabitants, its narrow valley settlement attracting visitors seeking the therapeutic benefits of radioactive waters. Johanngeorgenstadt, founded two centuries later by Protestant refugees, had transformed from a silver-mining outpost into a small industrial centre dominated by textile and glove manufacturing. Yet for all their differences, residents of both towns remained largely unaware of the strategic value lying beneath their feet. The Second World War would irrevocably alter both towns' fates, binding them to uranium's material agency in profoundly different ways.

Jáchymov (formerly Joachimsthal) originated from the medieval settlement of Conradsgrün along an old trade route in the Kingdom of Bohemia. In 1516, the discovery of a large silver vein amongst thick crusts of black pitchblende sparked a "Berggeschrey" (mining rush) that transformed the modest settlement into a prosperous mining town. By 1945, before intensive uranium extraction began, Jáchymov counted around 6,500 inhabitants. The town's distinctive morphology—a long, narrow urban fabric stretching along both slopes of a picturesque valley—directly reflected its medieval origins and the constraints of mountain terrain.

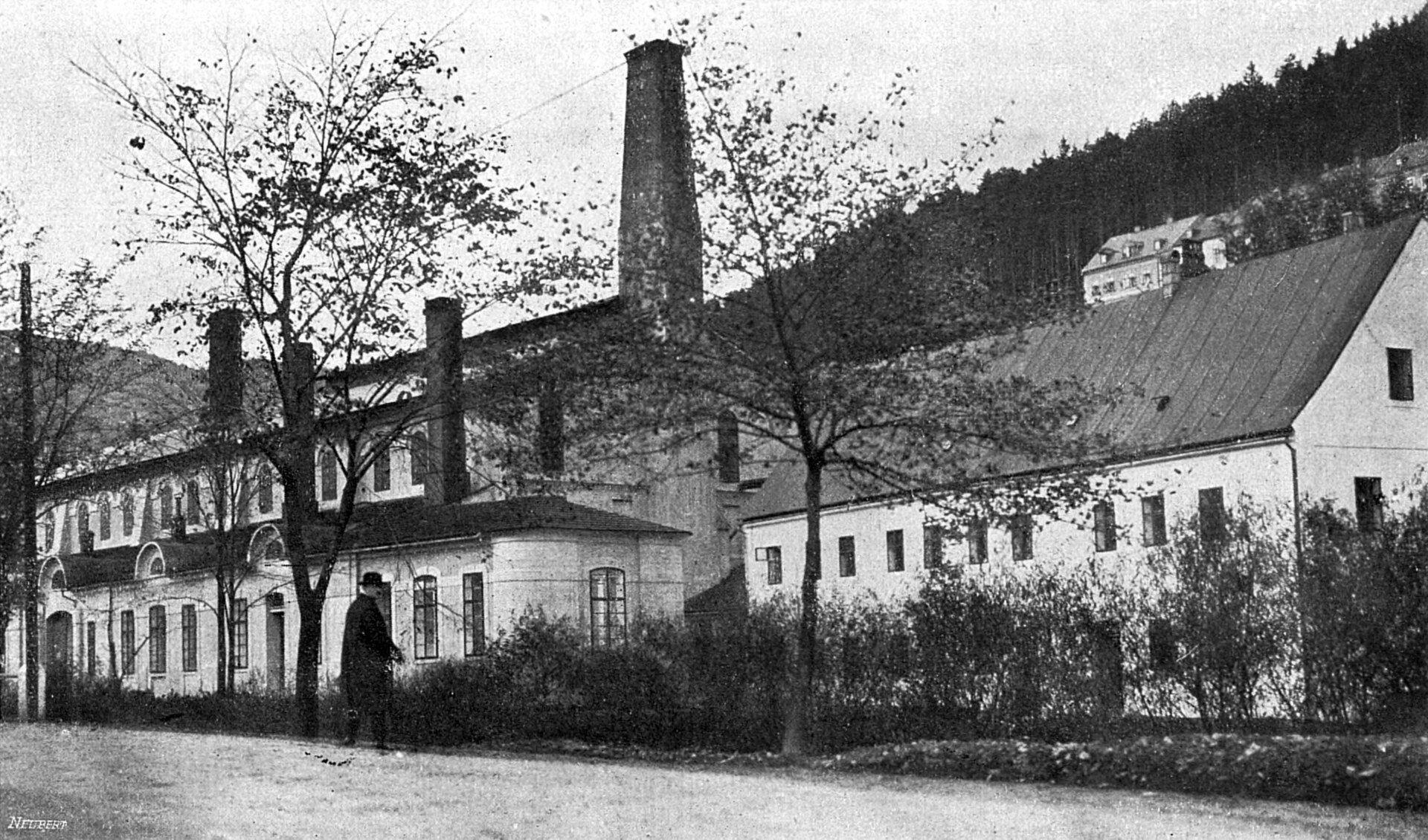

Pitchblende's distinctive yellow hues awakened it from obscurity. In 1852, the Bohemian chemist Adolf Patera was commissioned to develop an industrial process for extracting uranium colours from the black mineral. By 1856, the former silver metallurgical plant in Jáchymov was remodelled into the K.K. Urangelbfabrik—the Imperial-Royal Uranium Yellow Factory—producing up to eight types of yellow colour and one orange, soon exported to Great Britain and France with great demand.

Following the discovery of radioactivity and the Curies' isolation of radium from Jáchymov pitchblende in 1898, attention turned to the therapeutic potential of the region's radioactive mine waters. In 1906, the first private radon baths opened, drawing on water pumped from the Svornost Mine. The remarkable healing effects sparked a radium craze, and by 1912, the sumptuous Radium Palace Hotel opened its doors—the world's first radium spa. Designed by Viennese architects and financed by Count Ernst Silva-Tarouca, the neoclassical palace catered to an international clientele. At its peak in the 1920s and 1930s, Jáchymov accommodated up to 9,000 spa guests annually. Marie Curie herself visited in 1925, lending scientific prestige to the booming spa industry.

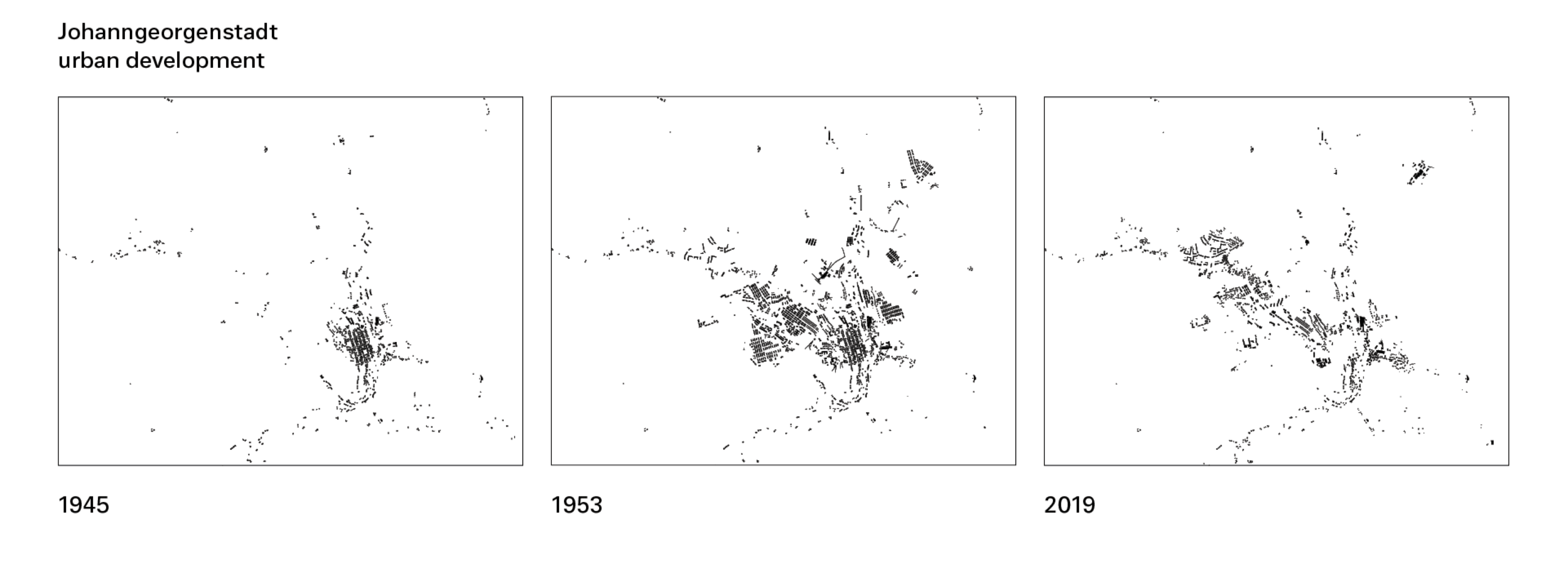

Johanngeorgenstadt was founded in 1654 by Bohemian Protestant refugees fleeing the Counter-Reformation in the wake of the Thirty Years' War. Named after its benefactor, Saxon Elector Johann Georg I, the town received the title of "freye Bergstadt" (free mining town) and within three decades operated more than 100 mines extracting silver, tin, and iron. The historic town was laid out on an orthogonal grid with a main square anchored by church and town hall, surrounded by smaller hamlets and older settlements typical of the region's mining towns. By the mid-nineteenth century, Johanngeorgenstadt had evolved into a centre of textile and leather glove manufacturing—earning it the nickname "German Manchester"—with thousands employed in factories and home workshops. Before the Wismut era began, the town counted fewer than 1,000 permanent inhabitants.

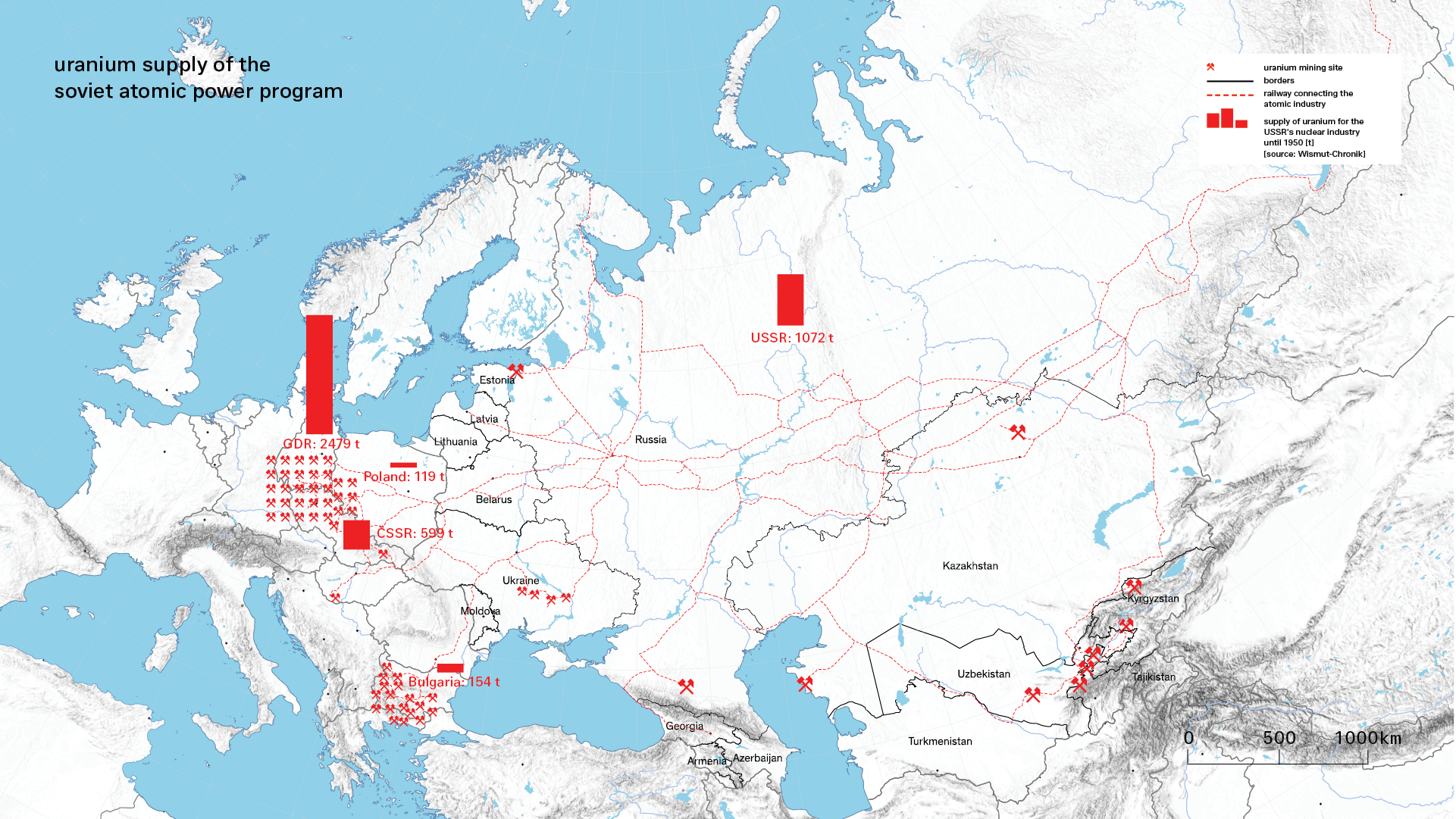

The Run on Uranium – Geological Restrictions and the Centralization of Peripheries

One of the principal initial obstacles confronting the Soviet Union's Atomic Programme was that Tsarist Russia possessed no uranium-based pigment industry, necessitating an immediate search for natural resources. Although the Uranium Problem Commission was established in July 1940, it proved ineffective and was disbanded following the German invasion. Soviet physicists began a modest research programme in February 1943. Despite attempts to exploit mines in Central Asia—particularly at Taboshar in Tajikistan from 1943 onwards—the project stagnated owing to inferior ore concentrations compared to Western sources, and the remote locations made extraction laborious and prohibitively expensive.

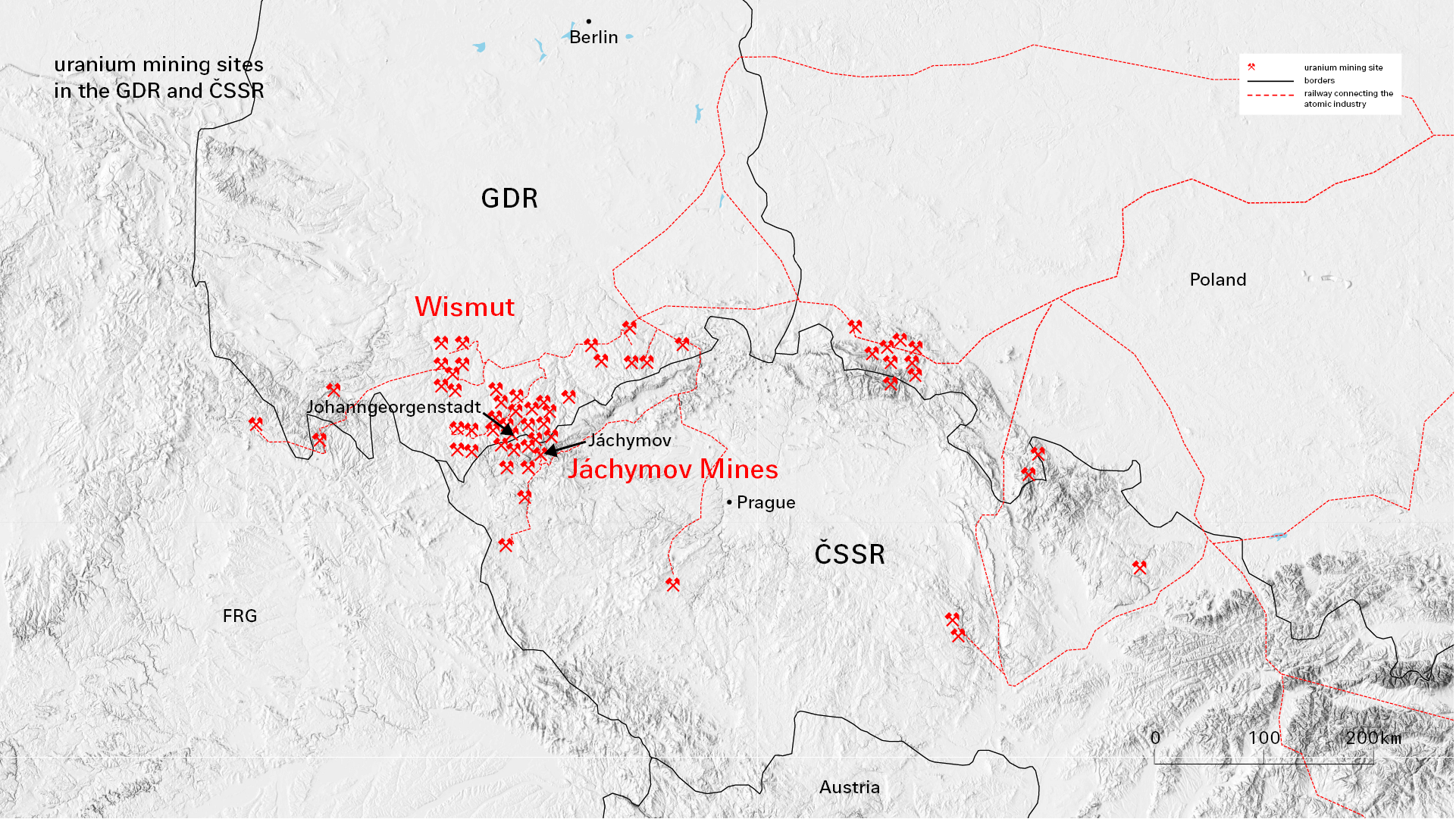

The situation transformed dramatically in 1945 when Soviet troops stormed Berlin and Brandenburg, dismantling German nuclear laboratories in Dahlem and Lichterfelde, and securing uranium stocks from the Auergesellschaft facility in Oranienburg. Besides equipment and considerable quantities of uranium, the military also transported scientists and their families to the Soviet Union. With the Red Army's advance into Germany and Czechoslovakia, the traditional uranium deposits of the Erzgebirge/Krušnohoří region—with its centuries-old mining heritage—suddenly came within reach, with Johanngeorgenstadt and Jáchymov emerging as the primary sites for immediate exploitation.

In 1946, miners working under Soviet military supervision brought the first uranium ore from the historic Frisch Glück shaft in Johanngeorgenstadt to the surface, marking the commencement of a uranium rush that would transform the entire region into a geopolitical hotspot. Both Johanngeorgenstadt and Jáchymov became the initial epicentres of an expanding uranium mining territory that would evolve into a globally significant producer until the disintegration of the Soviet Union.

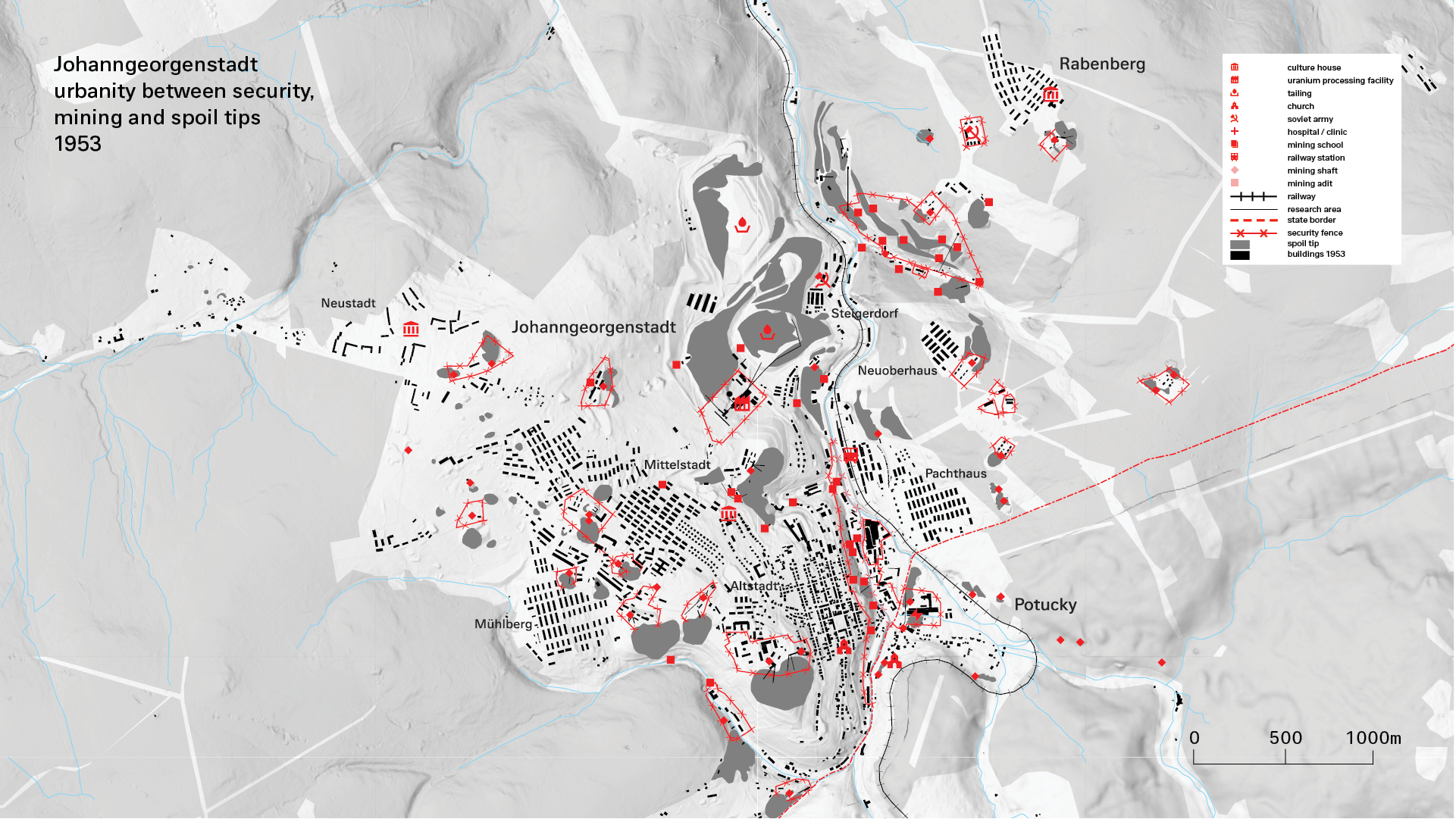

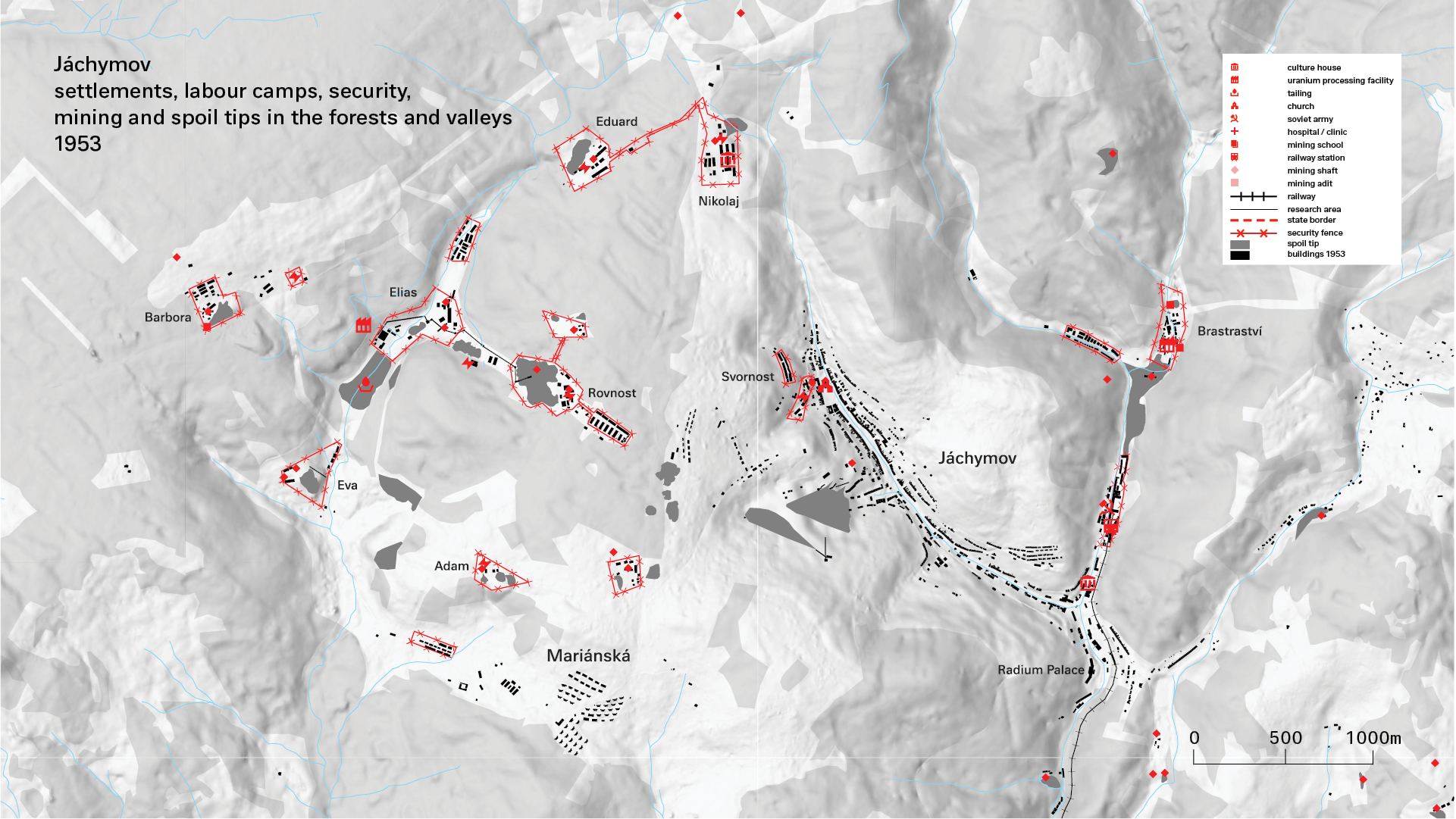

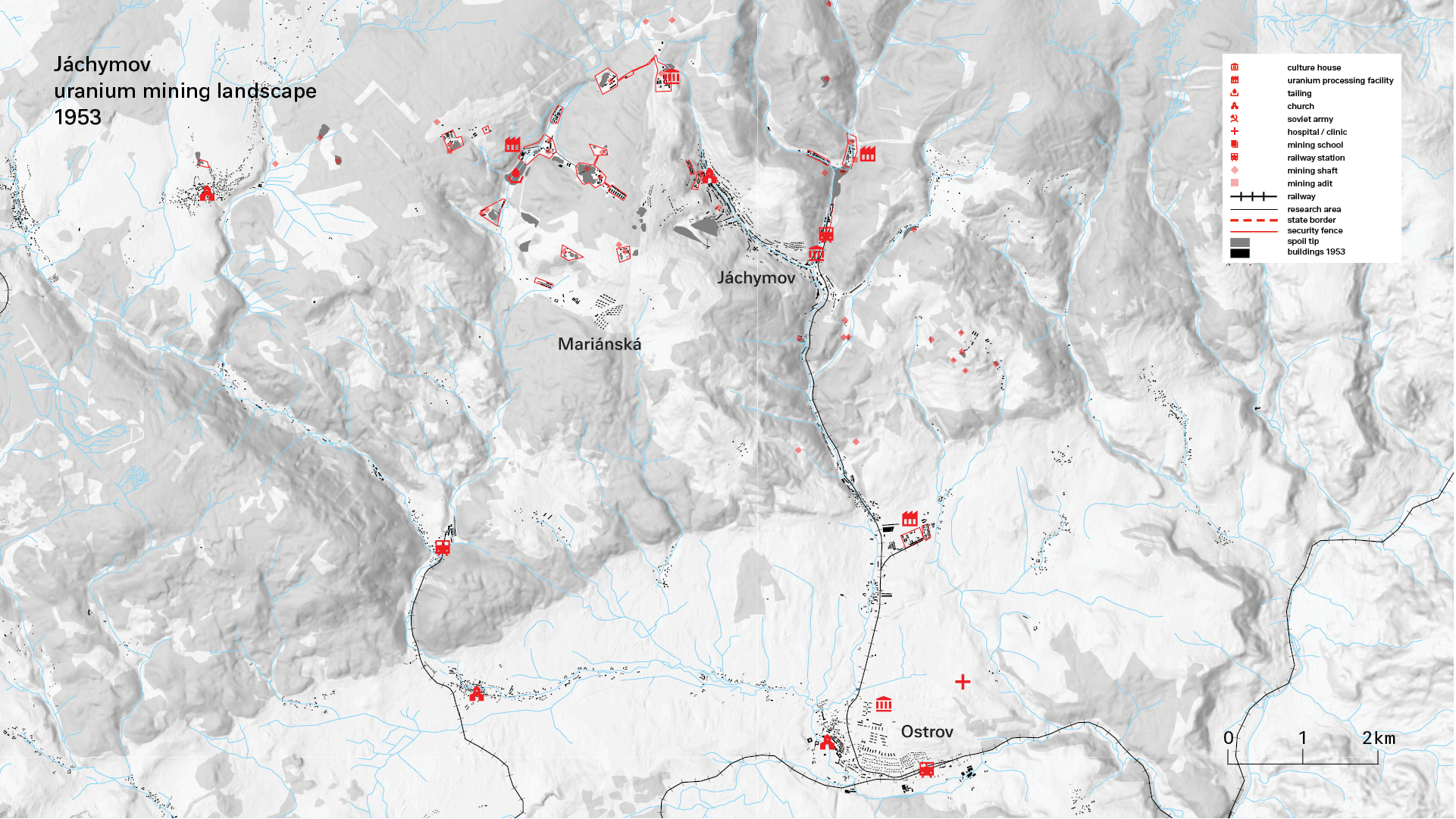

The establishment of SAG Wismut in 1947 (later SDAG Wismut from 1953) and the state-owned Jáchymov Mines fundamentally altered both cities and their subterranean and surface landscapes. The territorial reorganisation to extract massive resources and channel them through supply chains to the USSR created sealed security zones—veritable states within states, hermetically isolated from their surroundings. In East Germany, the Wismut territories operated under direct Soviet military control, whilst in Czechoslovakia, security zones encompassed Jáchymov, Horní Slavkov, Příbram, and other sites, which became strictly guarded no-go areas after 1948.

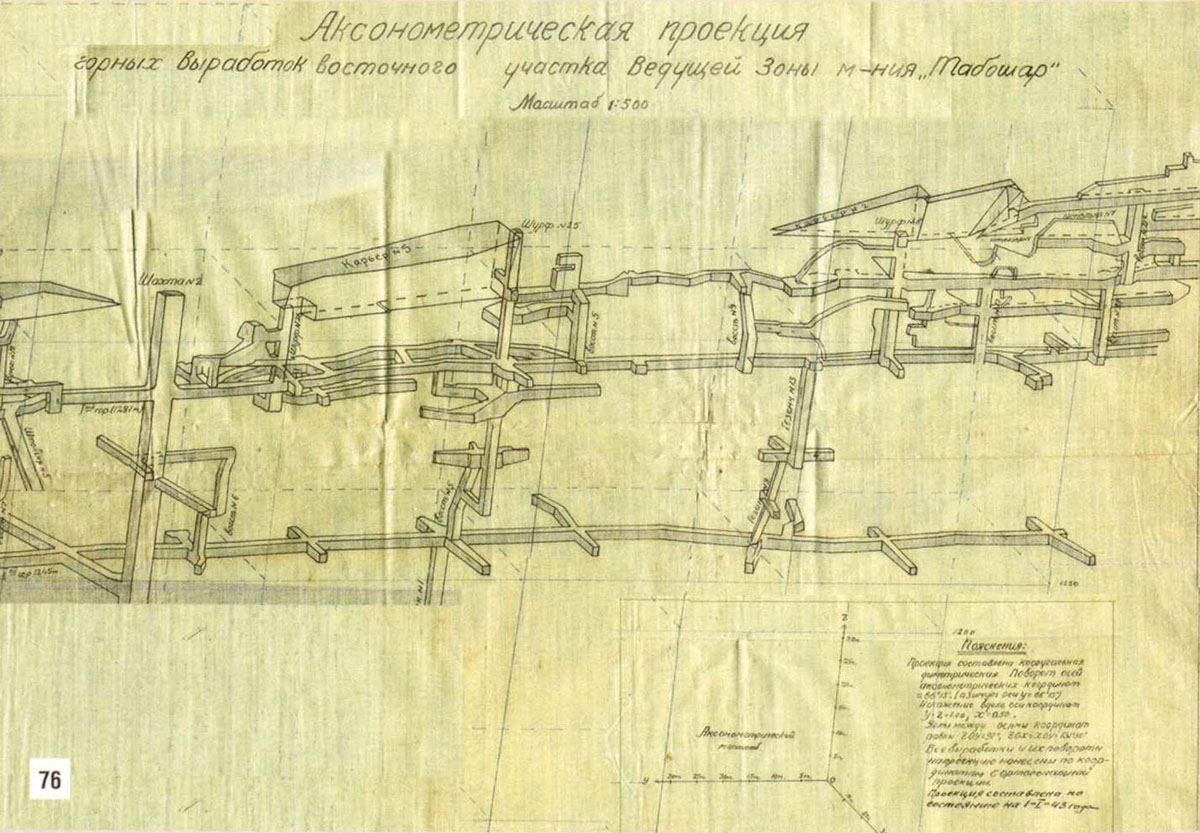

Axonometric projection of the mines of the eastern section of the field ‘Taboshar'. 1944

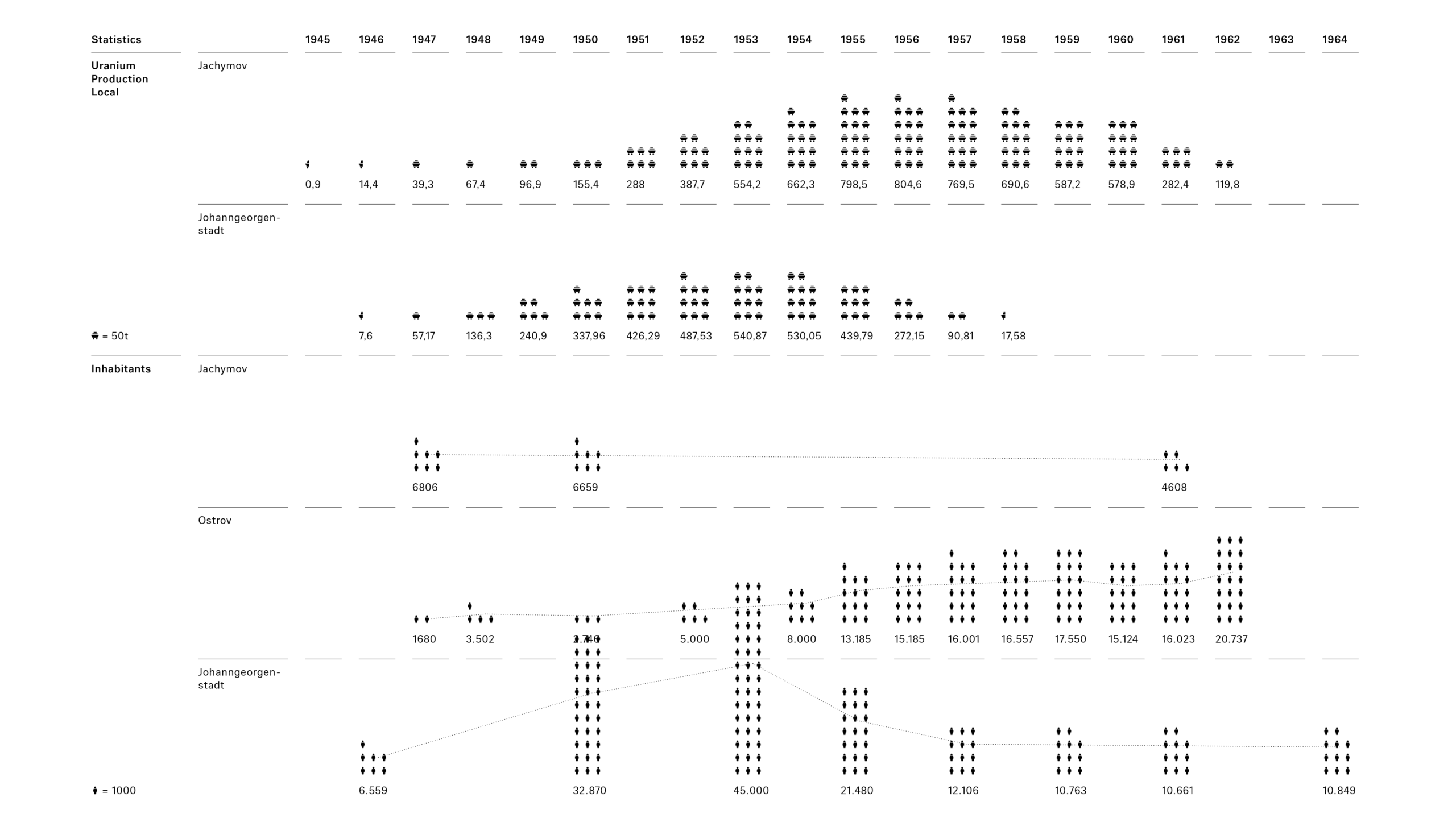

Mining uranium ore required a colossal workforce. Although characterised by a long-standing montane tradition and some industrial development, the settlements within the valley of the Erzgebirge/Krušnohoří were absolutely inadequately prepared for the rapid extraction and 'atomic urbanisation' to come. The early years until the beginning of the 1950s were marked by transformation shock, acute housing shortages, and severely challenging social conditions, resulting in improvised or temporary solutions. By 1952, in less than six years, Wismut AG employed more than 220,000 people across its territories in Thuringia and Saxony, both regions consisting primarily of smaller towns.

The Czech side experienced similar pressures: the Jáchymov Uranium Mines reached approximately 50,000 workers in 1955, including over 10,000 political prisoners. Given that most civilian workers migrated to the mining areas together with their families, the pressure on the towns' and villages' capacity was immense.

The transformation of the settlements unfolded in three distinct stages:

- Makeshift displacement and expropriation (Johanngeorgenstadt 1946-49, Jáchymov and Ostrov 1945-46)

- Camps and miners' settlements (Johanngeorgenstadt 1949-53, Jáchymov and Ostrov 1946-53)

- New socialist mining towns (Johanngeorgenstadt 1953-58, Jáchymov and Ostrov 1953-59)

Symptomatically, after the decline of uranium production, the city of Johann Georgenstadt entered a fourth stage—lasting considerably longer than any of the others—characterised by shrinkage (1958-present).

When the Soviet Army arrived in summer 1945, they commandeered administrative buildings and requisitioned bourgeois villas, whilst billeting soldiers with local residents or converting cultural and industrial facilities into makeshift dormitories. Yet even these measures failed to meet basic needs—troops spilled into surrounding settlements, creating murky jurisdictional boundaries between military occupation and civilian administration. Mining dictated everything: the shaft administration determined labour requirements; the city scrambled to house them and as it accelerated, the influx intensified daily. Despite displacement of local inhabitants and the forced retreats of civilians wherever possible, new construction was necessary yet proved difficult.

The first wave of housing expansion employed prefabricated wooden construction systems derived from late Nazi Germany's Osterweitertung programme, as well as barracks and components salvaged from former POW camps. By 1947, "Mühlberg" emerged as the first partially complete section of this camp-style development. These temporary timber structures were subsequently converted into more permanent masonry buildings, and the first Bergarbeiter Siedlungen (miners' settlements) emerged with Pachthaus, Rabernberg, and Mittelstadt.

With the demolition of the historic centre of Johanngeorgenstadt due to mining activity, a new wave emerged: the development of a dedicated Planstadt (planned city) and socialist mining town at Neustadt. Although never completed, it embodied the growing aspirations to create a symbolic expression of future mining prosperity and progress, despite the enduring harsh realities its inhabitants were exposed.

Despite its early spa infrastructure, housing the workforce needed for large-scale mining operations in Jáchymov proved impossible. In order to shelter the daily growing number of people needed to expedite the operations, the existing housing stock in the town and its surrounding villages was largely expropriated. However, run down and left in uninhabitable conditions by the departing German residents, this proved insufficient. The steep topography of the valley furthermore restricted any meaningful housing expansion, forcing uranium mining operations to locate largely forced labor in catastrophic conditions very close to the shafts themselves.

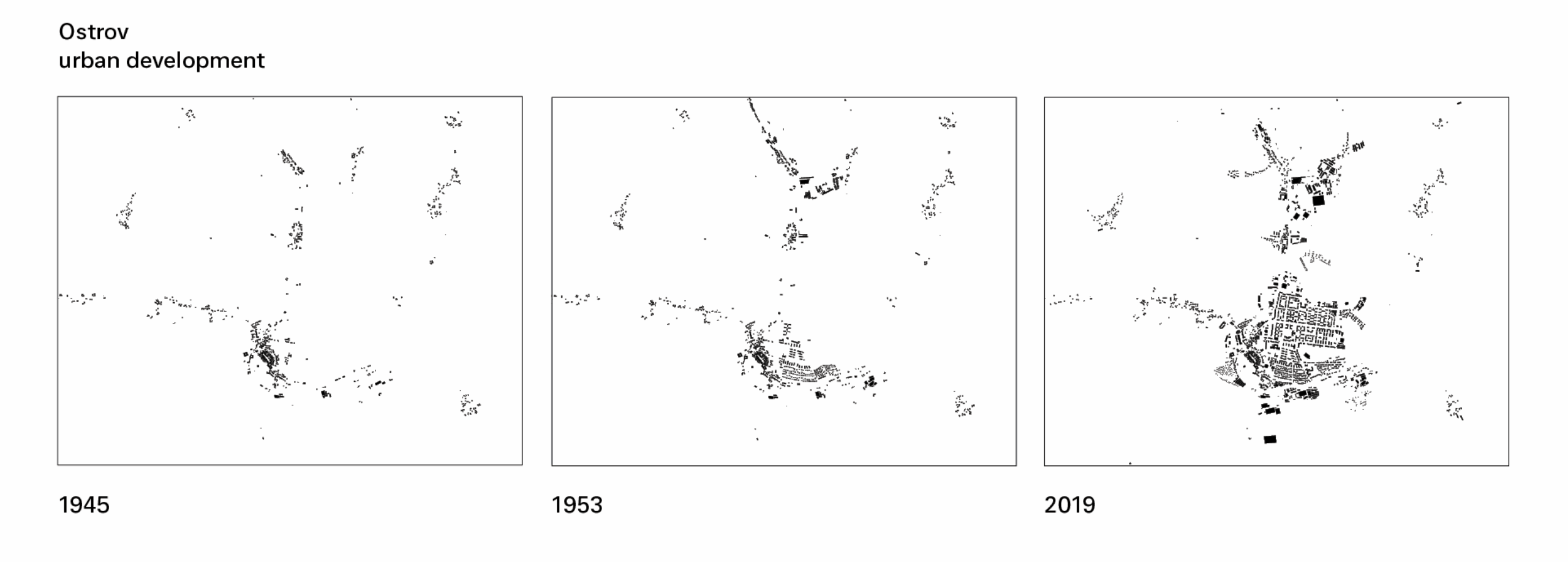

While these forced labor and POW camps became incorporated into the restricted zones that were dispersed in the woods around the town, future development was redirected towards the nearby railway town of Ostrov. Its favorable topography proved transformative. The first newly built housing units dedicated to the civilian miners were rather small, concentrated settlements of provisional barracks of improvised character, emerging along the street connecting Ostrov and Jáchymov (near Horní Žďár) and around the railway station in Ostrov. A small colony of simple wooden double houses (the so-called "Finnish" type), put into use in 1949-1950, was located directly next to the Ostrov train station and the new settlement in Mariánská.

The pivotal moment came in 1953 when JUM commissioned an entirely new settlement—aptly named Nový Ostrov (New Ostrov). Originally planned for 16,000 residents, the scheme was progressively expanded to accommodate 25,000.

Nový Ostrov concept merged garden city principles with symmetrical compositions and orthogonal street networks, centered on Mírové náměstí (Square of Peace), framed by a monumental House of Culture and residential blocks with commercial ground floors. Architecturally, the settlement tracked Czechoslovakia's political trajectory: initial rudimentary structures gave way to Socialist Realist ornamentation between 1948 and 1955—sgraffito facades with animal and vegetable motifs, pilasters concealing panel joints, bold portal chambranles, and ubiquitous sun symbols—before gradually fading towards more restrained modernism by the 1960s.

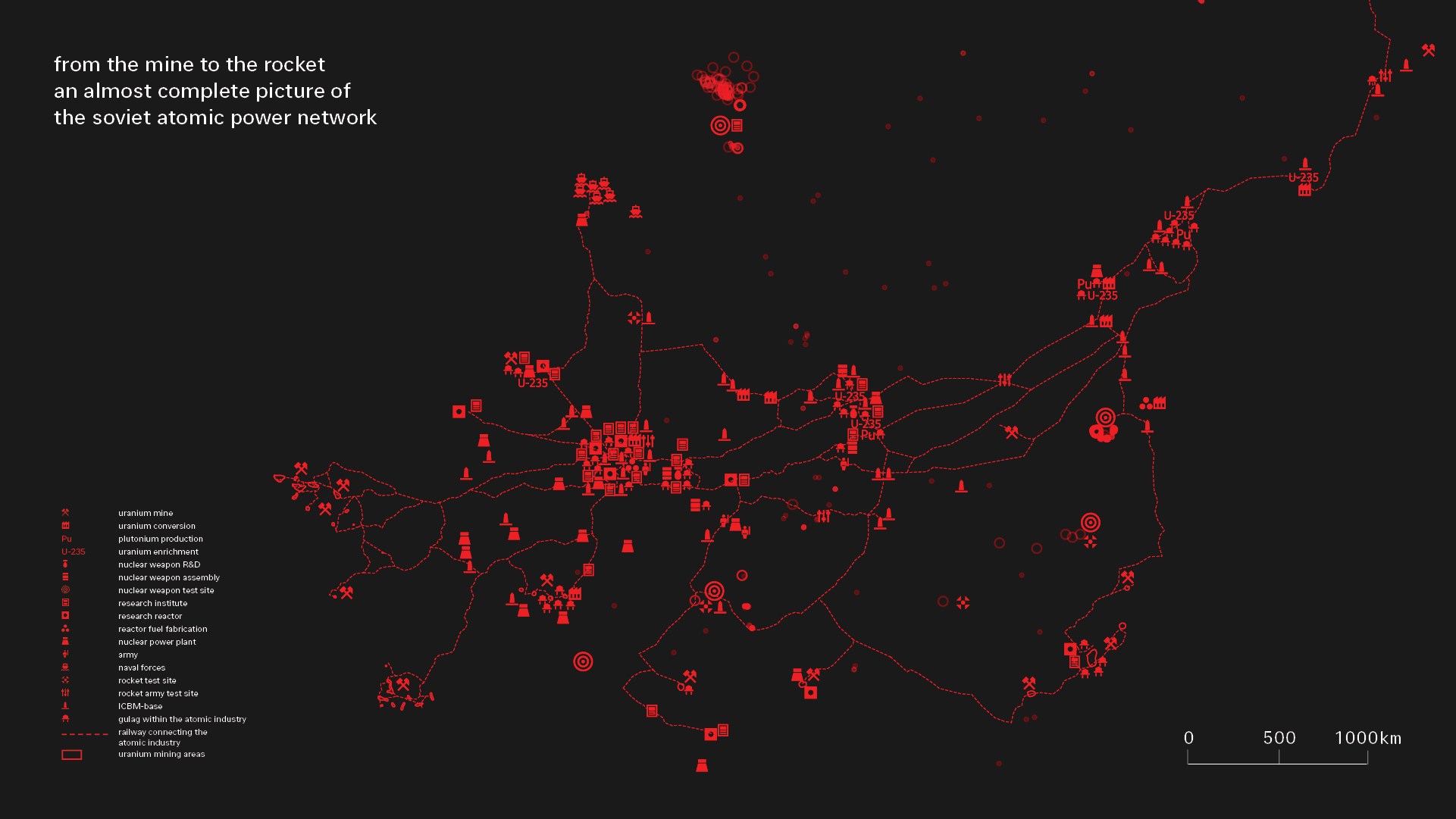

The transformation extended far beyond the mining settlements themselves. To produce atomic fuel and nuclear weapons, an entirely new industrial complex emerged around the conversion of natural uranium arriving in ever-escalating quantities from the Soviet Union's peripheries. Transmuting essentially low-grade ore into fission-based explosives demanded operations at every conceivable scale simultaneously: from engineering invisible subatomic forces in laboratories to constructing factory complexes the size of towns; from redrawing transnational mobility routes to administratively reorganising vast territories.

Nuclear projects were continental projects: vast undertakings that depended not only on the intellectual power of elite scientists and the massive output of industrial centres, but relied thoroughly on the availability of copious natural resources, on remote hinterlands to conceal operations and absorb contamination, as well as on the organisational power to synchronise all of this. Only a very limited number of global powers were initially extensive enough to achieve this in the two decades after the war.

Many facilities rivalled small towns in scale, employing thousands of workers and requiring enormous quantities of land, power, water, transportation infrastructure, security apparatus, housing, and essential amenities. These emerging infrastructures shaped landscapes of resource circulation that facilitated uranium's movement across continents. The intricate networks served dual purposes: transporting highly restricted information and materials whilst simultaneously disposing of colossal quantities of unwanted substances through deliberate and inadvertent leakage, spills, and waste streams along the entire production chain.

Creating the atomic core for the RDS-1 required three principal industrial sites.

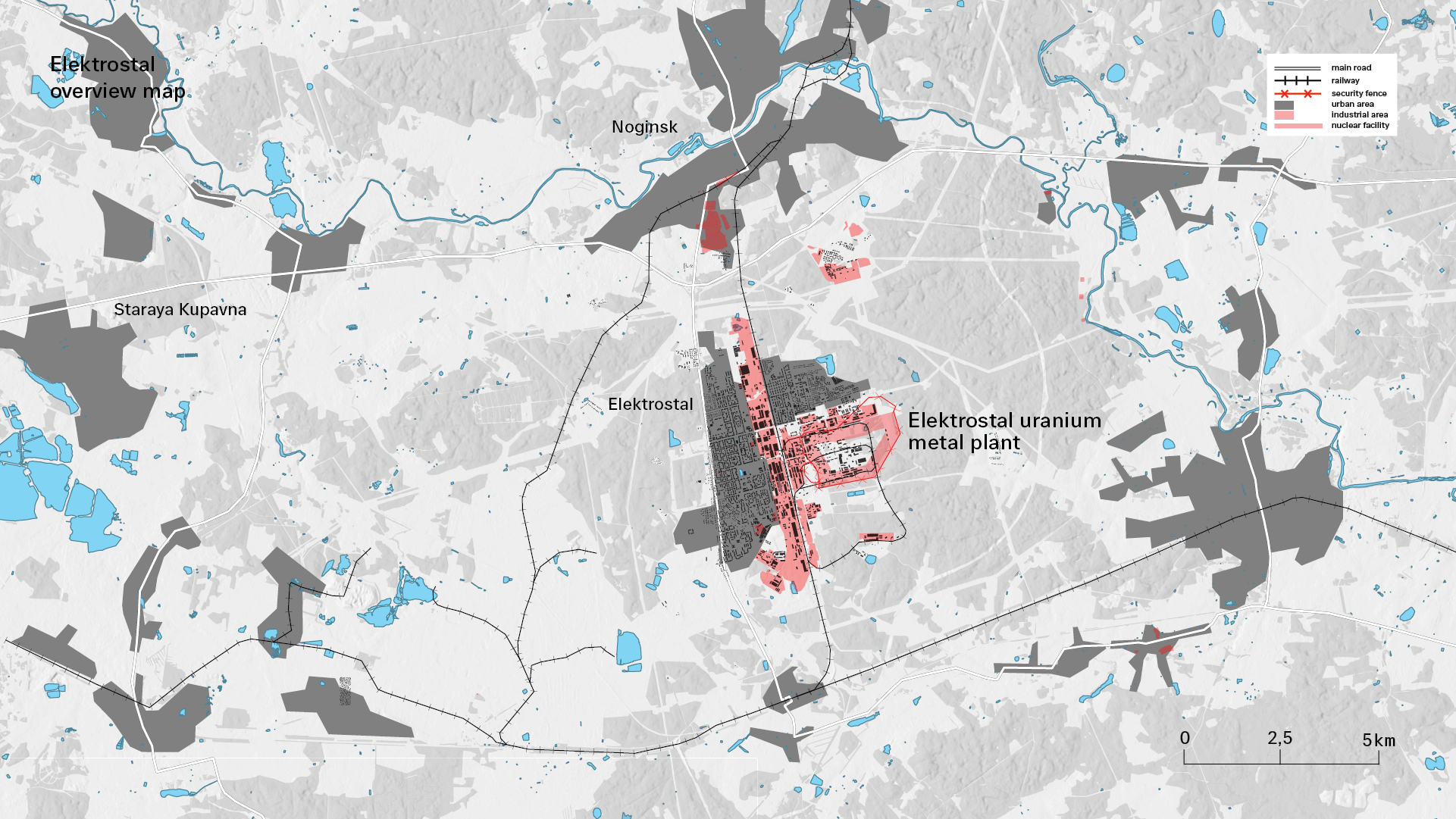

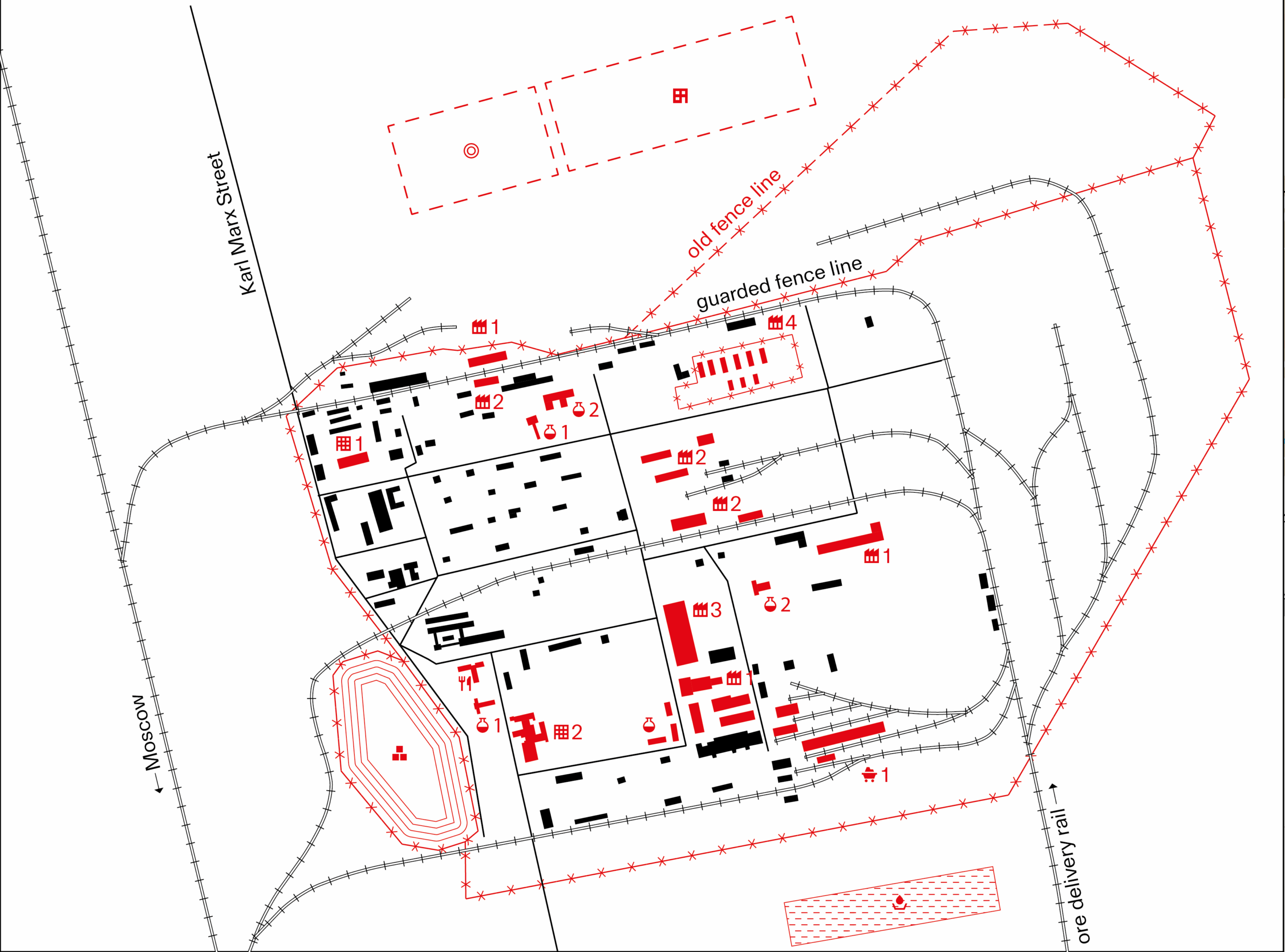

Elektrostal

The industrial city of Elektrostal was home to a facility known as to Plant 12 or the “Machinery Manufacturing Plant” (MSZ), one of Russia's pilot facilities in uranium processing, conversion and metallurgy. From 1946, the plant's main task lay in the production of uranium metal and its fabrication into fuel in the form of canned uranium slugs and, later, uranium hexafluoride for the production of highly enriched uranium.

Whilst much of the Soviet Union's eventual nuclear programme remained a nationalist endeavour, the initial expertise required to engineer sufficient uranium metal did not originate from Soviet soil. By the mid-1940s, their programme still lacked fundamental knowledge, yet new resources had become available through conquest. Among these was Nikolaus Riehl, a German radiochemist who had directed uranium production at the Auer Company in Oranienburg. Following Soviet occupation, Riehl led operations at Elektrostal from 1945 until 1950, becoming instrumental in developing the Soviet bomb and subsequently earning the Stalin Prize for his contributions to RDS-1. Born in St Petersburg and fluent in Russian, Riehl possessed intimate knowledge of the German equipment being dismantled and relocated, enabling him to continue his previous work under Soviet supervision.

From 1946 onwards, British intelligence tracked regular uranium ore shipments from the newly occupied Jáchymov facility to Plant 12, where wet-chemistry processes extracted, melted, and cast the uranium. The plant fabricated fuel for the experimental F-1 reactor and later for plutonium production reactors at Chelyabinsk-60, whilst also processing highly enriched uranium for the weapons assembly laboratory at Arzamas-16. Production depended on uranium hexafluoride from Ukraine and metallic calcium shipped from I.G. Farbenindustrie Bitterfeld in East Germany. By the 1950s, operations gradually transferred to newer, more secure complexes in the Urals and Siberia.

...

Elektrostal exemplifies an anomaly in the fledgling Soviet Union's nuclear infrastructure development, as it presented the conversion of existing war-time infrastructure within an existing industrial center. The city, located 70 kilometres east of Moscow, evolved from an agglomeration of villages centered around steel factories established by industrialist Nikolay Vtorov in 1916. Following nationalisation after the October Revolution, the settlement adopted the name Elektrostal in 1928, reflecting its newly electrified steel plants. When Nazi Germany invaded in 1941, Soviet leadership relocated substantial portions of military industry to locations throughout the Russian heartland, transforming Elektrostal into a significant production site. The town's steel mills were complemented by munitions and heavy machinery facilities. Following the war's conclusion, portions of the complex dedicated to defence production underwent conversion. Within the former munitions plant, the Soviets established Plant 12, one of their first facilities producing nuclear reactor feed materials. Despite never becoming a "closed" or "secret" city like several Soviet nuclear towns, Plant 12 occupied approximately 2.5 square kilometres within a secured fence line. The facility contained roughly 150 buildings, divided administratively into two sections—zavod A and zavod B—handling experimental and main chemical processing operations respectively.

Chelyabinsk

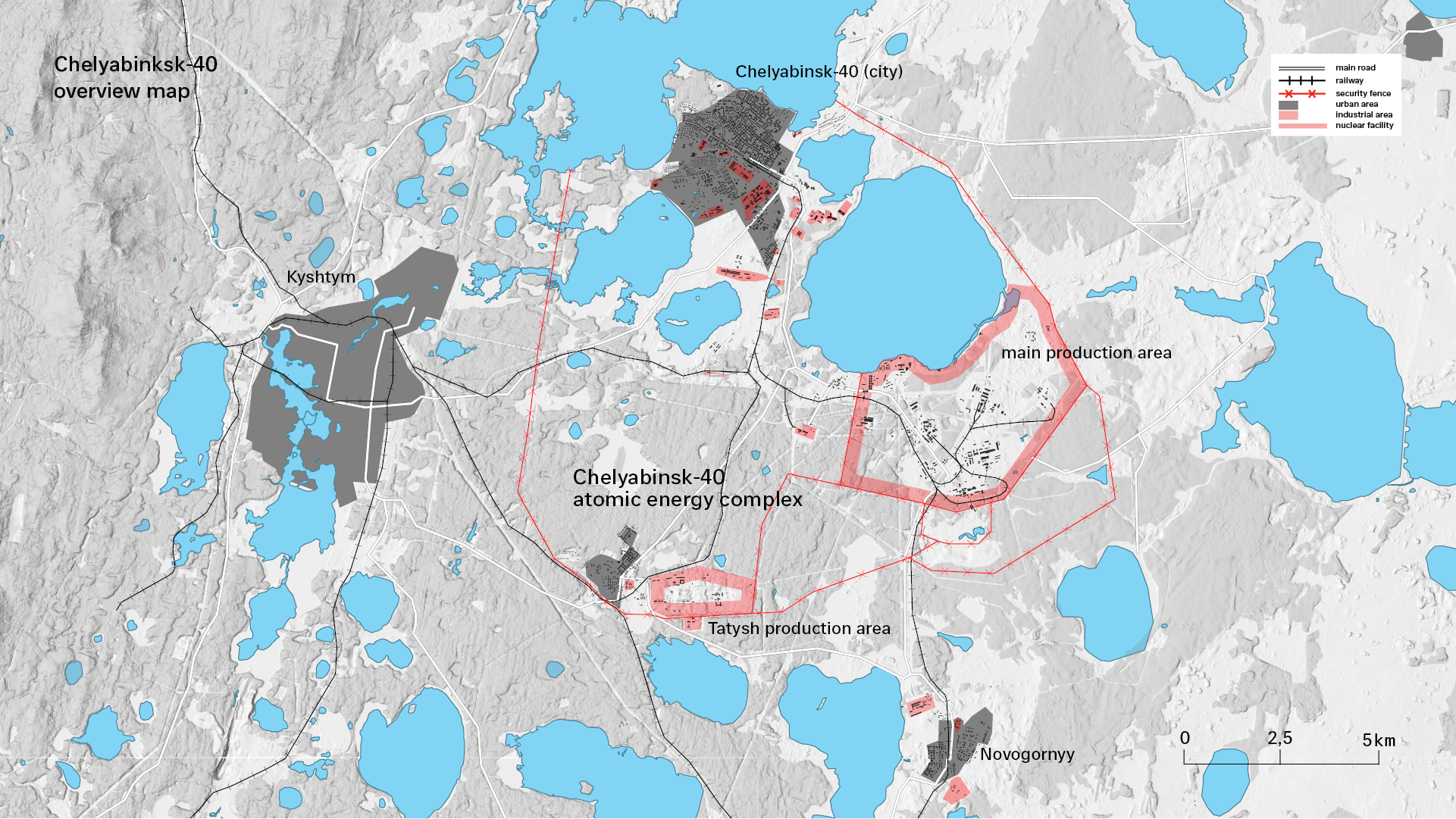

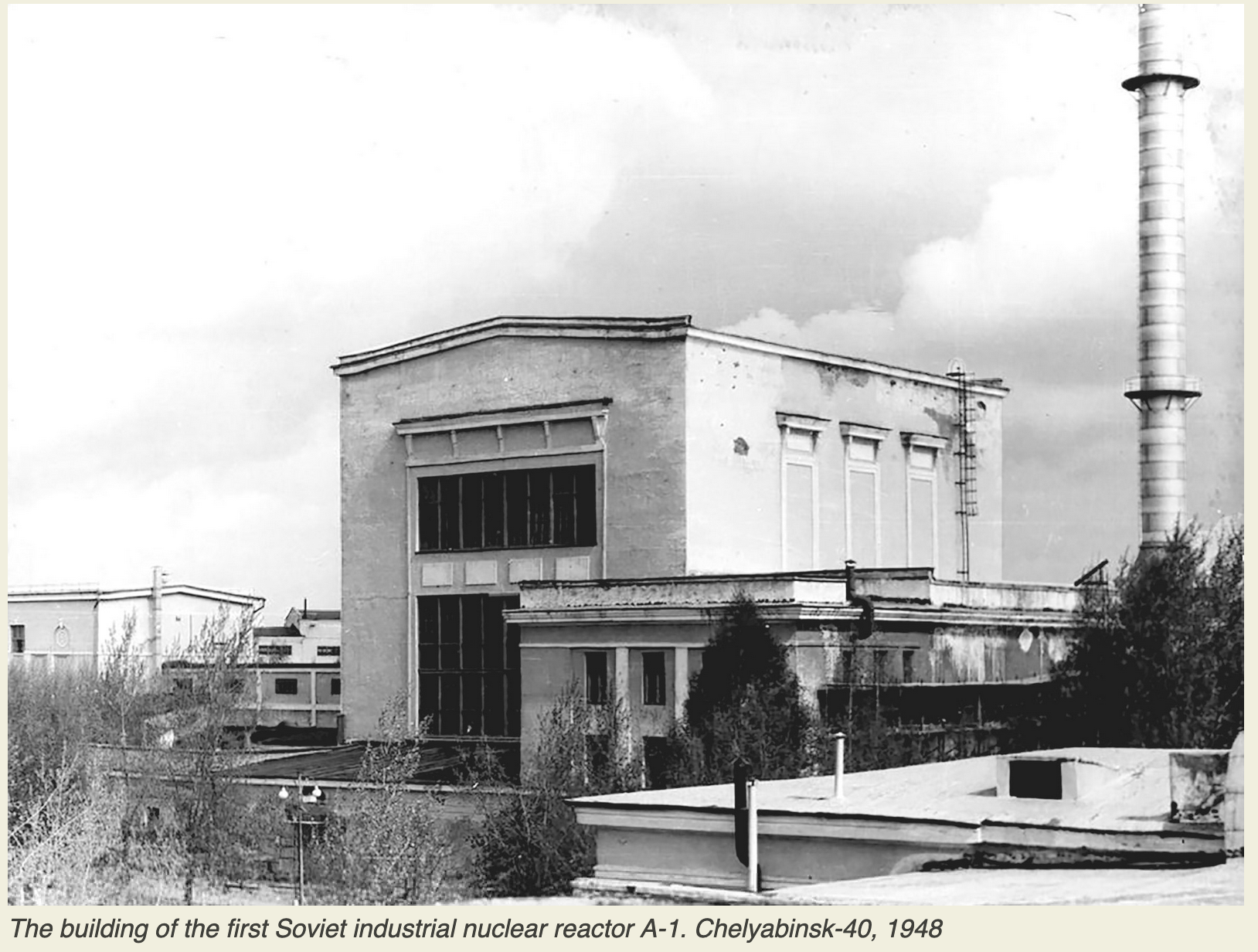

Chelyabinsk-40 (later designated Chelyabinsk-65) was the Soviet Union's first industrial plutonium production facility, located in remote territory 80 kilometres northwest of the city of Chelyabinsk. Unlike Elektrostal, which adapted existing industrial infrastructure, this complex was purpose-built to serve the emerging nuclear assembly line. Beginning operations in 1948, it performed three main tasks: generating plutonium through neutron irradiation, chemically separating it from irradiated fuel, and refining it to a grade and purity suitable for nuclear bomb cores.

The production area eventually occupied approximately 200 square kilometres, partitioned initially into three main facilities—reactors, chemical separation, and metallurgy. It furthermore incorporated a substantial urban settlement, administrative quarters, NKVD security installations, railway stations, and utilities for water, electricity, and steam. Like a vast machine, the site was permeated by innumerable pipelines, cables, roads, and railway tracks that maintained its complex metabolism.

To prevent unauthorised access, the area was declared a special regime zone and enclosed by double-rowed fences, guard posts, watchtowers, and NKVD patrols. Inhabitants of existing hamlets within this perimeter were relocated, landowners expropriated. Beyond the gates, an even wider buffer zone cleared the adjacent region of unwanted minorities and "politically dangerous" individuals. The same strict security regime prevailed internally, isolating the plutonium production stages from one another. Beyond the material itself, which moved from one area to the next, only a limited number of plant managers, political leaders, and chief scientists possessed access across sectors.

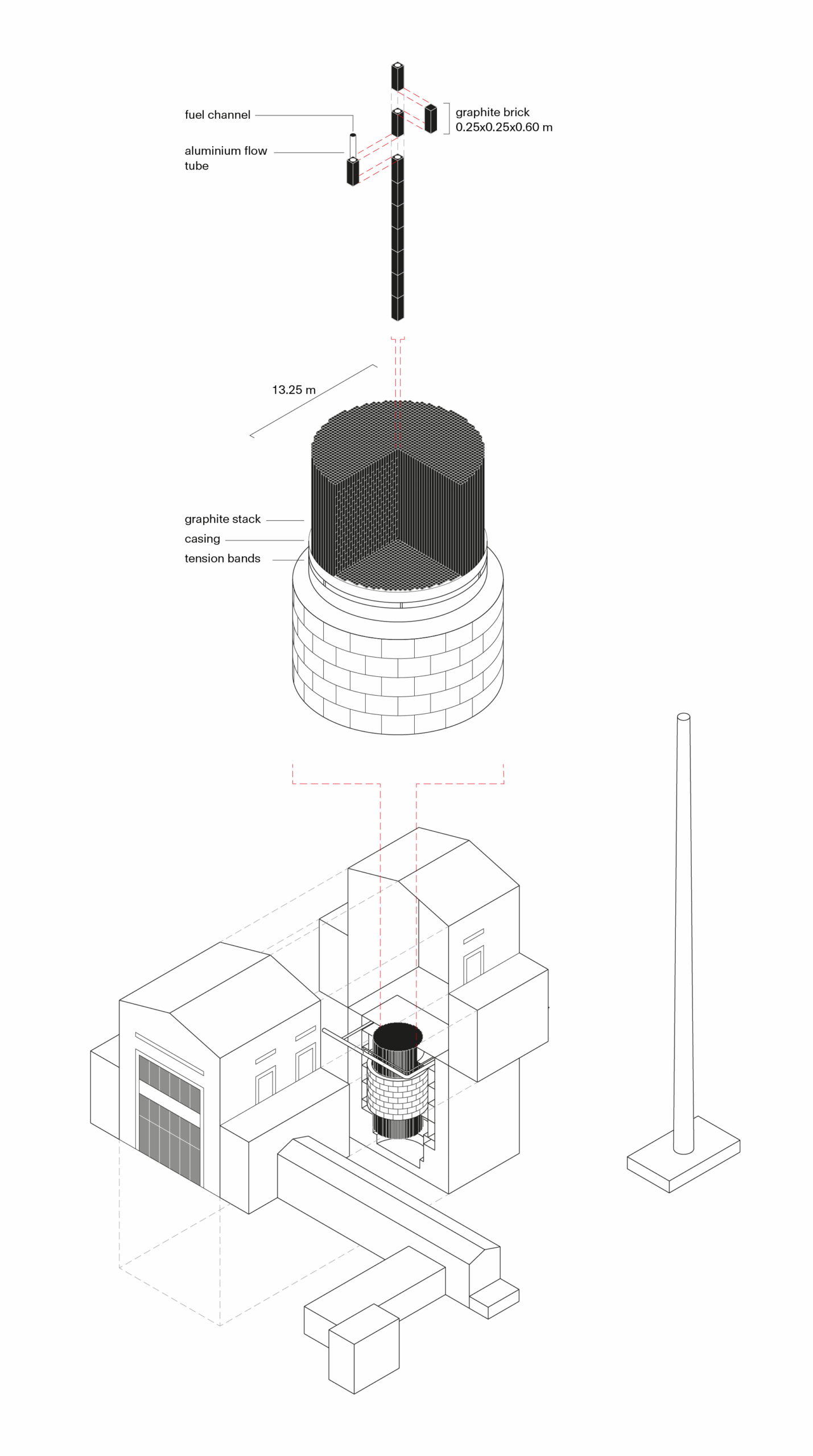

The generation of plutonium occurred in five uranium-graphite reactors—A, IR, AI, AV-1, and AV-2—constructed between 1948 and 1955 along the lower banks of Lake Kyzyltash. There, aluminium-clad uranium fuel rods, fabricated at Elektrostal's Plant 12 and transported by dedicated railway, were loaded into vertical cores and irradiated for approximately one hundred days. Once calculated quantities of plutonium had transmuted, the rods were released into cooling ponds for several weeks, allowing short-lived radioactive isotopes to decay whilst gaseous fission products were released through large smokestacks into the atmosphere.

To support the immense production cycles at Chelyabinsk-65, tens of thousands of workers had to be recruited from across the Soviet Union within a short timeframe. "Base-10"—as the initial cluster of barracks was called—arose on the peninsula's northwestern periphery, deliberately distanced from the catastrophic conditions prevailing in construction camps near the manufacturing plant. Originally conceived to shelter two thousand specialists, the settlement possessed no viable master plan to anticipate rapid growth. Despite official promises made to attract qualified volunteers, arrivals encountered prison-like conditions in a bare barrack town. Surrounded by watchtowers and double fences, inhabitants found themselves isolated from the outside world as a paranoid security regime banning external contact for years was imposed. Movement was meticulously registered, whilst housing and food remained scarce, with electricity and sanitation reserved for elites.

In 1948, authorities commissioned a master plan transforming the settlement into a modernist city of Stalinist appeal, yet progress remained sluggish. The watershed arrived with Stalin's death and Beria's execution in 1953. Under Khrushchev's reforms, Base-10 received city status in 1954, and workers gained authorization to leave in 1956—triggering an acute labour crisis. To retain scarce specialists aware of dangers they faced, living conditions had to surpass anywhere else in the Soviet Union. By 1958, the city began to boast amenities and social infrastructure beyond most Soviet citizens' lifestyle. Closed, concealed, and severed from the outside world it would become an urban anomaly of splendor and wealth as well as sickness and toxicity.

Arzamas

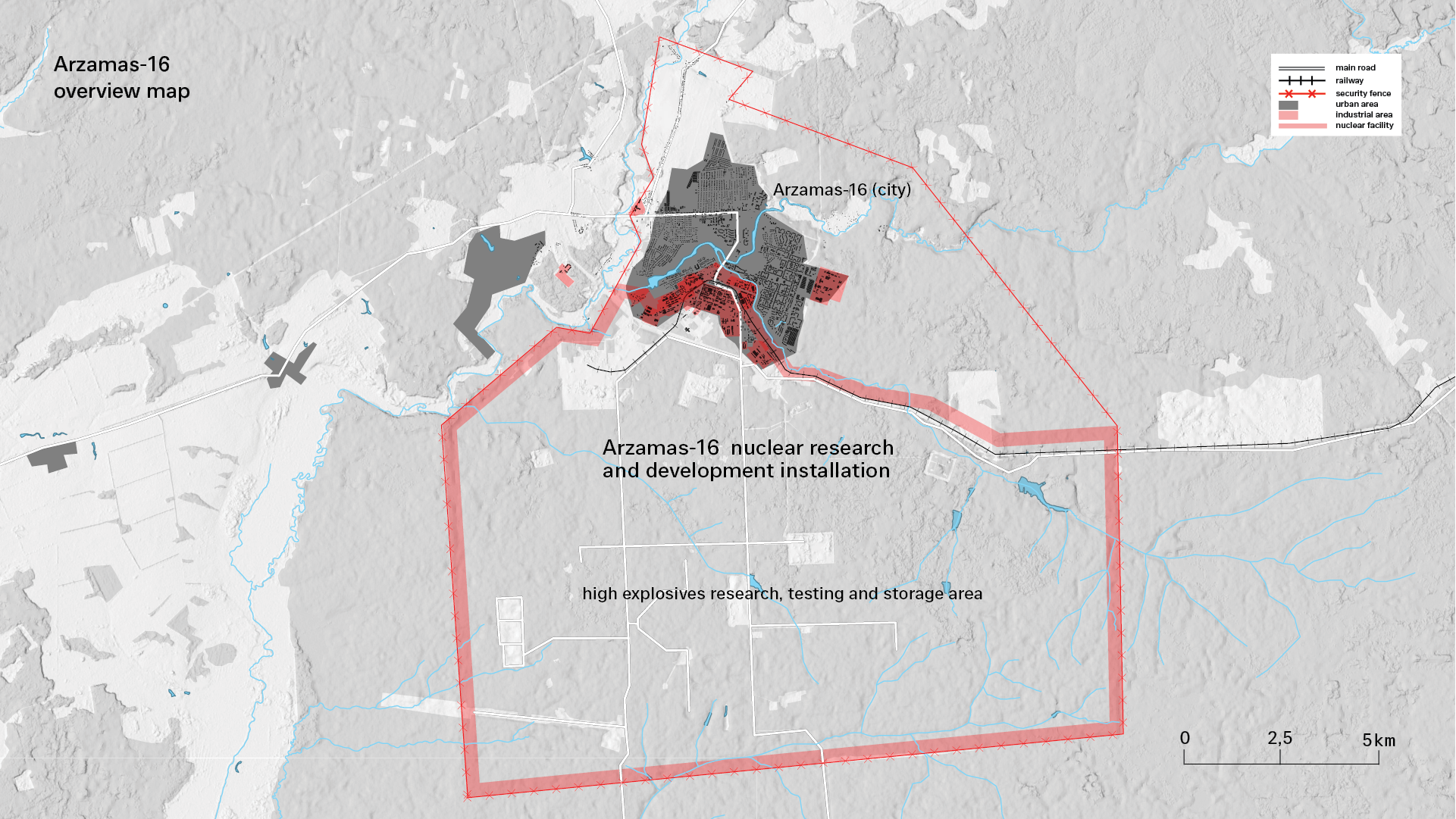

Arzamas-16 (also known as "Arzamas-75", "Kremlev") was a closed city housing the nuclear weapons design laboratory KB-11, responsible for the design and assembly of the RDS-1 bomb to be transported to Test Site No. 2—Semipalatinsk-21—for detonation trials. Founded in April 1946 as a subordinate organisation of Laboratory No. 2 in Moskau, the site was selected to satisfy Stalin's requirement that critical facilities remain within 400 kilometres of the capital to reach within a days travel. The large surrounding woodlands provided natural concealment from areal reconnecains for the secret city and nuclear research complex. In 1946, owing to stringent security measures, the location was removed from all maps. Construction of facilities commenced in May 1946, with a closed zone established around the site by February 1947 and complete isolation achieved by 1948.

The complex developed comprehensive testing capabilities, including facilities for aerodynamic studies and evaluation of nuclear devices under various operational conditions—vibration, climate, and deployment scenarios. Until 1951, Arzamas-16 housed the Soviet Union's only nuclear warhead assembly facilities. In 1951, the first serial production plant, Avangard, became operational in the western sector of the restricted area, whilst experimental facilities occupied the southern forests.

The secret city developed on the grounds of Sarov, site of the former Sarovsky Hermitage, an Orthodox monastery established in 1706. Following the monastery's liquidation in 1927, the settlement served various industrial purposes, producing shells and mines as "Plant No. 550" during the Second World War. From June 1946 onwards, the plant was transformed into the nuclear weapons design laboratory, and Sarov disappeared from all maps.

The central urban area was located around the former monastery complex, whilst the nuclear research and development installations expanded southward through largely forested terrain. Like Chelyabinsk-40, the site was secured by three major fence lines: one encircling the entire city, a second surrounding the installation area, and a third enclosing specific facilities.

In 1947, construction of a settlement for nuclear scientists and engineers began on the left bank of the Satis River, designed to provide an elevated standard of living including sports, cultural, and intellectual amenities. A central sports stadium was completed by 1948, followed by a dramatic theatre in the former monastery buildings in 1949. The city's rapid growth manifested in educational infrastructure: before 1946, only one school existed; by September 1949, a second opened, with five additional schools constructed between 1953 and 1957, and six more between 1959 and 1962. In 1954, Arzamas-75 was granted city status by the same secret decree that elevated Chelyabinsk-40. Accommodation, infrastructure, and cultural facilities continued expanding throughout the decade, with permanent railway traffic established in 1952. Aptly nicknamed "Los Arzamas" in reference to the American weapons laboratory at Los Alamos, the city exemplified the privileged conditions necessary to retain scarce scientific talent in the Soviet nuclear programme.

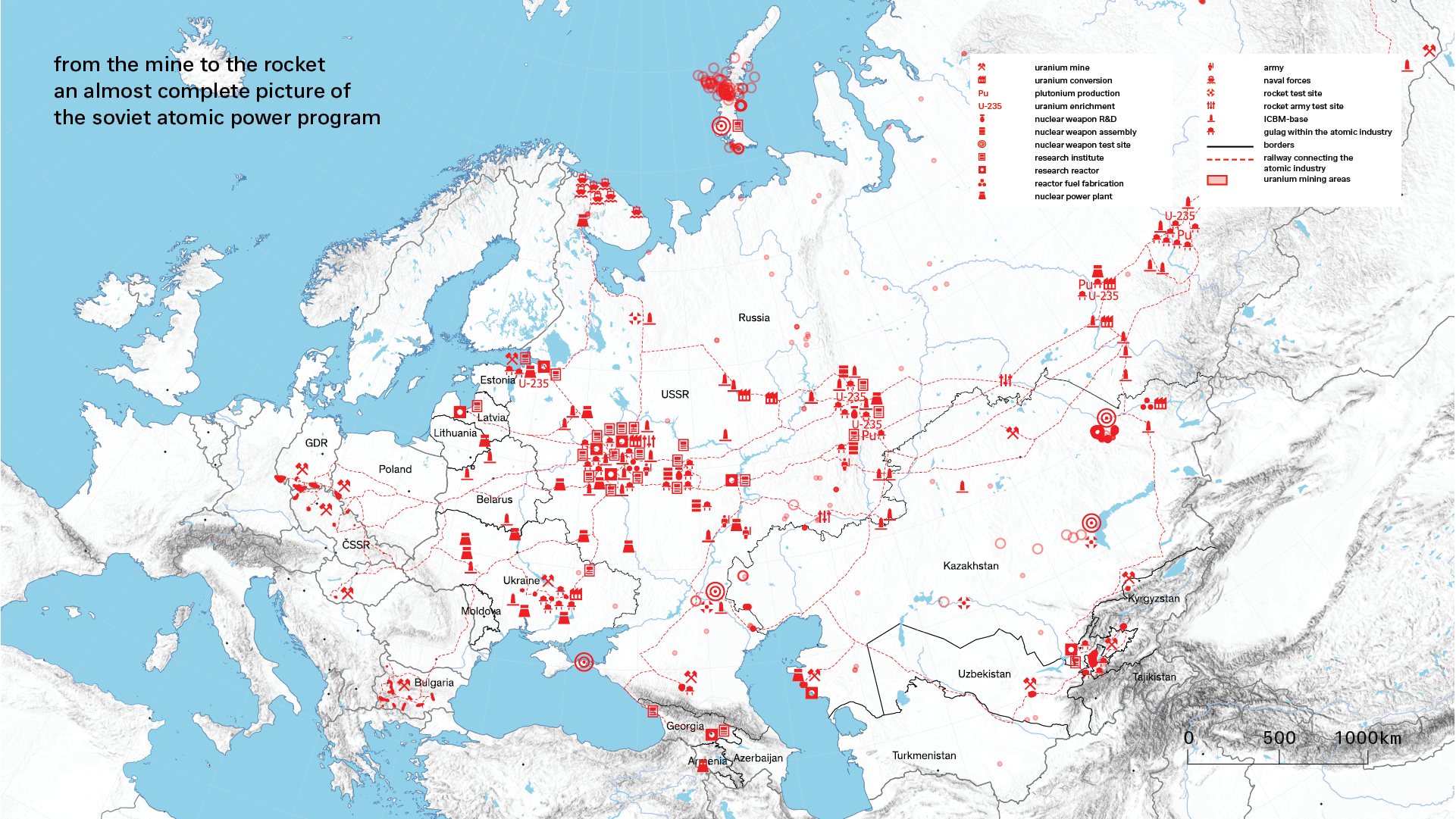

Over its 42 years of operation, the nuclear test site at Semipalatinsk-21 witnessed an estimated 456 nuclear weapons tests. When operations finally ceased in 1991, the disintegrating USSR possessed roughly 35,000 strategic warheads—a startlingly high number given that the stockpile had already been reduced by approximately 20 percent since the mid-1980s. Peak production capacity for nuclear weapons manufacturing and refurbishment remained unclear, though official reports placed the figure between 2,000 and 7,000 warheads annually. Between 900,000 and 1,000,000 people were estimated to have been employed across the Soviet nuclear industry at the time of the USSR's collapse, dispersed over nearly 150 different sites. The accumulated stockpile of pure uranium totalled more than 200,000 tons, whilst within half a century, 144 tons of plutonium-239 had been produced—a highly radioactive and toxic element with a half-life of 24,110 years.

This continental system channelled and concentrated colossal quantities of radioactive material across the Eurasian landmass. To the west, it began with mines and facilities in occupied Eastern Germany, Czechoslovakia, and the Baltic States, extending through reactor complexes around European Russia to industrial installations stretching from the Urals deep into Siberian territories. It connected the harbours of the Murmansk fleet and test grounds at Novaya Zemlya in the Arctic to the nuclear-powered facilities at Shevchenko on the Caspian Sea, from underground mines and shelters buried hundreds of metres into the lithosphere to satellites and spacecraft in orbit. The system depended on numerous academic institutions, peripheral uranium mines, remote test sites, distributed rocket silos and launch platforms across land, air, and sea, alongside a parallel civil nuclear industry.